Climatic Environmental Simulation

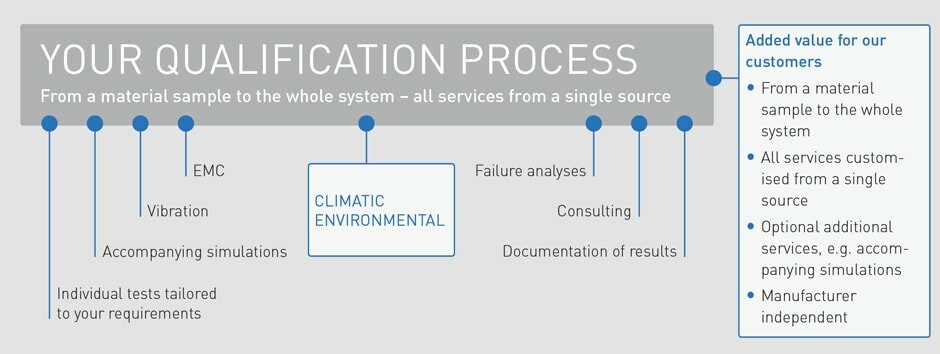

Climatic environmental simulation is anchored in numerous standards and is a necessary part of the qualification process for technical systems. We provide the required tests for you in a comprehensive manner, independent of industry and manufacturer.

We run your test objects through the desired, tailor-made test program including computer simulations, vibration tests, EMC tests and the actual climatic environmental simulations. A failure analysis, e.g. according to VDI 3822, is a possible option to round off the service package. Talk to us – also about our certification according to TISAX and accreditation by DAkkS. We would be glad to advise you personally.

By activating this video the external provider might be able to collect user specific data by activating this content. For more information please check out our data protection.

IABG climatic chambers

Climatic environmental simulation: Year-round - Realistic - Reproducible

Test Facilities 0,1 m3 to 180 m3

• High Altitude Chamber (GHK) up to 3,800 m above sea level

• Conditioning Units and Preheating Hall

• Temperature Chamber (TK)

• Climatic Chamber (KK)

• Vehicle Chamber I & II

• Climate Combination Chamber

• Temperature Shock Units

• Temperature and Climate Cabinets

• Combination test cabinet (BFV 64)

• Vacuum chamber (UK) up to 20,000 m above sea level

• Pressure change systems

• Solar Simulation Unit

• Splash water test unit

• Dust test cabinets

• Salt fog cabinets

• Contamination units

• Ozone test facility

- Tests on electrical components (e.g. actuators and drives) according to LV124 with supply and control of the DUTs during the environmental tests

- Carrying out parameter tests to record relevant characteristic data of the DUTs to prove correct function

- Communication with peripheral devices

- VDA ISA TISAX zertifiziert für die Labels „Informationen mit sehr hohem Schutzbedarf“, „Prototypenschutz“ und „Datenschutz“ für die Standorte Ottobrunn und Lichtenau

- ISO 14001

- ISO 9001

- DIN EN ISO/IEC 17025 for Fatigue Strength Laboratory

- DIN EN ISO/IEC 17025 für das Betriebsfestigkeitslabor - Verzeichnis der Prüfverfahren

- Accreditation Calibration Lab for Mechanical Units according to DIN EN ISO/IEC 17025

![[Translate to English:] Klimatische Umweltsimulation: Temperatur & Feuchte](/fileadmin/_processed_/c/7/csm_Umweltsimulation_temperatur-feuchte_440px_dde324107d.jpg)

![[Translate to English:] Klimatische Umweltsimulation: Höhe und Luftdruck](/fileadmin/_processed_/3/6/csm_Umweltsimulation_hoehe-luftdruck_440px_dd4df4d004.jpg)

![[Translate to English:] Klimatische Umweltsimulation: Sonne](/fileadmin/_processed_/6/2/csm_Umweltsimulation_sonne_440px_31a96bf265.jpg)

![[Translate to English:] Klimatische Umweltsimulation: Dichtigkeit](/fileadmin/_processed_/b/4/csm_Umweltsimulation_Dichtigkeit_440px_abe7a7c553.jpg)

![[Translate to English:] Klimatische Umweltsimulation: fluide und korrosive Umgebung](/fileadmin/_processed_/b/d/csm_Umweltsimulation_fluidekorrosive-umgebung_440px_126ec37142.jpg)

![[Translate to English:] Mechatronik](/fileadmin/_processed_/8/5/csm_Mechatronik-Umweltsimulation_9e2fa7b96a.jpg)