- Services

-

Test services and analysis

- Acoustics

- Ballistic investigations, pyro-shock testing

- Determining mass characteristics

- Electromagnetic compatibility

- Testing and fatigue strength

- Services for the construction and agricultural machine industry

- Fatigue strength testing laboratory

- Flight tests

- Functional tests

- High temperature tests

- Climatic Environmental Simulation

- Magnetic field measurement / magnetic field simulation

- Modal test surveys (EMA, OMA)

- Product qualification

- Qualification of Electrical Connectors

- Advanced Composites and Plastic Material

- Qualification & Certification Medical Technology

- Failure Analysis

- Shock Simulations for Naval Platforms

- Structural tests

- Thermal vacuum tests (TV,TB,TD)

- Survivability, vulnerability & effect on target

- Vibration and shock

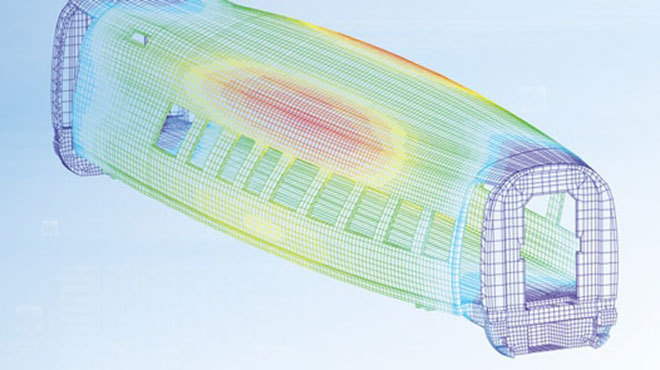

- Virtual Testing

- Space Simulation

-

Testing and fatigue strength

Testing and fatigue strength

At our headquarters in Ottobrunn we have over 5,000 m2 of covered testing area (halls) with a modern infrastructure, central hydraulic, compressed air and cooling water supply as well as safety facilities (e.g. plant fire brigade).

On our standard and special test benches we test, try out and qualify entire vehicles, functional units or individual parts and components. In doing so, we examine the dimensioning, the constructive design, the construction and the materials used as well as the behaviour under defined parameters.

We also develop innovative test devices. We would be pleased to advise you individually - already in advance, during the entire production period or in case of specific problems.

Automotive: Our range of services in testing and qualification:

➭ Complete vehicles

➭ Vehicle bodies

➭ Chassis

➭ Engine & powertrain

➭ Interiors

➭ Safeguarding mechatronic systems

➭ Consulting

Rail & track: Fatigue strength – accredited according to DIN EN ISO 17025

We offer you investigations on strength as well as various component tests from measurement and analysis to static test planning and evaluation.

➭ Our services for rail & track

Wind energy plants: Component tests and structural tests

✓ Testing of WTG components

✓ Functional, hardware-in-the-loop and endurance testing

✓ Environmental simulation on components

✓ Recording of operating loads

✓ Fatigue strength tests

✓ Static characteristic values

✓ Fatigue

➭ All services for testing and qualification of wind energy plants

Plant components: Testing and fatigue strength

We carry out comprehensive vibration tests and investigations on earthquake safety as well as material testing and failure analysis.

- DIN EN ISO/IEC 27001:2017

- VDA ISA TISAX zertifiziert für die Labels „Informationen mit sehr hohem Schutzbedarf“, „Prototypenschutz“ und „Datenschutz“ für die Standorte Ottobrunn und Lichtenau

- ISO 45001 (Locations Ottobrunn, Lichtenau)

- ISO 14001

- Verzeichnis der Prüfverfahren – Prüflaboratorium DIN EN ISO/IEC 17025 (Standort Lichtenau)

- BSI TR-03140 (TR-SatDS1G) Conformity assessment according to the sateLlite data security act

- ISO 9001

- DIN EN ISO/IEC 17025 for Fatigue Strength Laboratory

- DIN EN ISO/IEC 17025 für das Betriebsfestigkeitslabor - Verzeichnis der Prüfverfahren

- EN 9100

- Accreditation Calibration Lab for Mechanical Units according to DIN EN ISO/IEC 17025

- Accreditation of Testing Lab for Qualification Tests (PLQ) according to DIN EN ISO/IEC 17025

- Certification of Space Test Centre according to ECSS-Q-20-ST-07C

- BSI-certified IT security provider

- AEO (Authorised Economic Operator)