- Business Fields

- Automotive

-

Springs

- Fatigue strength of axle springs

- Fatigue strength of valve springs

- Corrosion Spring Testing Machine (CSTM)

- Dry Spring Testing Machine (DSTM)

- Valve Spring Testing Machine (VSTM)

- Variable Test Rig for Resilient Components (VTRC)

- Grit Impact Simulator Machine (GISM)

- Rotating Bending Test Machines (RBTM)

- Large Spring Testing Machine (LSTM)

- Spring Coil Test Machine (SCTM)

-

Corrosion Spring Testing Machine (CSTM)

Corrosion Spring Testing Machine (CSTM)

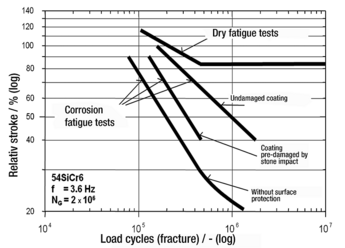

The Development and Quality Monitoring of resilient, highly stressed automotive components such as springs and stabilizer bars, requires testing that represents actual vehicle conditions as accurately as possible. There are some essential test areas when determining the quality of spring steel, for example, fatigue strength and setting behavior under realistic load and environmental conditions.

Based on these requirements, IABG offers a spring test machine capable of performing fatigue tests in both a salt water corrosion environment and a normal laboratory atmosphere. Thus allowing the determination of spring fatigue strength while reducing both time and cost.

Advantages of the IABG spring test machines

- Energy efficiency by utilising the principles of resonance in tests

- Reliability and low maintenance

- Designed to exclude all external forces and vibrations

- Testing with parallel and circular deflection

- Tests with original spring seats in installation position

- Dry and wet fatigue tests

- Integrated measurement of spring characteristic curves and spring setting

- Optional application of abrasive media to spring seat

- Software-based testing, documentation and evaluation

- Accepted by all leading car manufacturers

- Compliant with German OEM standards (AK-LH 07) of springs and stabilizer bars

Relevant influences on Springs

- Mechanical demands from

- Spring compression

- Axle kinematics

- Corrosive environment conditions

- Damage to the surface and coating through

- Abrasion caused by spring coil contact

- Stone impact

Experimental verification

- Pre-damage caused by stone impact

- Corrosion in alternating cycle tests developed by the German Association of the Automotive Industry (Verband der Automobilindustrie, VDA)

- Optional tests with simulated compression kinematics on full axle configuration

- Tests with original spring seats in installation position

- Fatigue test with cylic load and test with fixed or variable amplitudes

- Abrasive wear simulation

- Corrosion simulation through intermittent salt-water spray exposure

- Statistical validation through systematic testing and a sufficient number of test items

Technical data

- Test specimens:

parallel or circular deflection on springs of all types - Max. permissible load per test position:

Fmax = 40 kN - Number of possible test specimens per test:

2, 4, … limited by Fmax - Stroke (displacement control): S = 10 to 300 mm

- Max. Spring length: L0 = 750 mm

- Test frequency:

fo = 0,23 ... 0,33 √(n·R) [Hz] = 1,8 to 15 Hz

n = Number of test specimens tested

R = Spring rate [N/mm] - Salt water container (250 l) with singular programmable spray intervals and heating capability up to 50°C

- Weight / measurements of machine:

3,5 tons, L = 1800 mm, W = 2000 mm,

H = 2600 mm (additional space required for:

operator panel, switch cabinet, corrosion unit,

water treatment tank and hydraulic aggregate.)