Laser decontamination LaPlus

The decontamination of painted surfaces is one of the most labour-intensive steps in the deconstruction of nuclear facilities. Large areas of metal or mineral components have to be cleared of paint and impurities to enable clearance measurements. An additional challenge here is the removal of coating systems containing PCBs, because these are potentially carcinogenic. Using laser for removal burns the coating and the PCBs react and turn into harmless products.

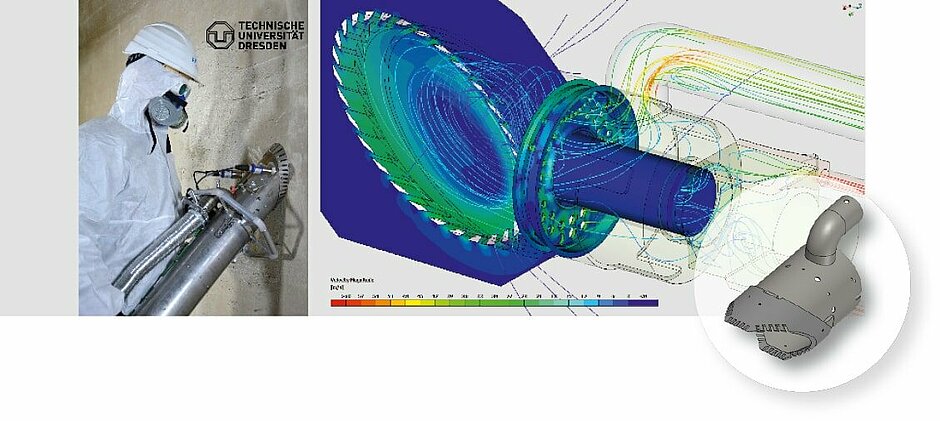

As part of a research project together with the TU Dresden and the TU Bergakademie Freiberg IABG developed a tool attachment for mobile use of the laser decontamination system. The aim of this research project was to transfer the findings from previous research projects from the laboratory to practical application. This was a success and was convincingly proven in trials on the premises of the reprocessing plant in Karlsruhe (WAK).

Our services

- Turnkey: development according to customer specifications through to realisation and commissioning

- Metal and concrete: material-specific tool attachments

- Flexible component configuration: modular design enables adjustment to surface properties (corners, for example)

- Testing before manufacturing: configuration of flow characteristics using FEM simulation

- Process monitoring: online monitoring for the disintegration of PCBs

- Flexible application: mobile or remotecontrolled utilization

Funding code: 1559215C

- 16.02.2024IABG-Gruppe veräußert EXTEDO GmbH an Bertelsmann Investments

- 21.11.2023IABG successfully certified according to ISO 27001

- 24.10.2023Vorbereitungslehrgang der IABG-Werkfeuerwehr zur Brandschutzfachkraft (IHK)

- 07.06.2023Safety for transport and storage containers of hazardous goods: New large drop test facility enables tests on containers up to 65 t

![[Translate to English:] [Translate to English:]](/fileadmin/media/Broschueren/U_GEO/Thumbnails/Flyer_Umwelt-Energie-thumbnail.jpg)