- Business Fields

- Automotive

- Development Services

-

Technical Calculations

- Fatigue Strength Assessment

- CAD Design, FE Modelling

- Fatigue Strength Analysis, Joining Techniques

- Method Development, Software Development

- Non-Linear Structural Dynamics, Shock, Fluid-Structure Interaction

- Damage-Equivalent Vibration Testing (FatiResponse)

- Oscillation, Vibration

- Structure Optimisation

- Fluid Simulations (CFD)

-

Fatigue Strength Assessment

Fatigue Strength Assessment

Ever shorter development times mean that computer-based fatigue strength evaluation and the synergy of testing and simulation are gaining increasingly in importance.

The service portfolio of IABG for fatigue strength testing includes the following:

- Computer-based fatigue strength assessment and Fatigue life – method development

- Materials specimen testing in the accredited IABG Fatigue Strength Testing Laboratory (IFL)

- Parts and components tests

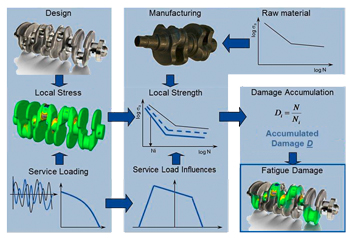

Computer-based fatigue strength assessment

Computer-based fatigue strength assessment is divided essentially into three areas:

- Determination of local service stress (static, cyclic, dynamic, stochastic)

- Determination of local strength taking into account technological effects (forging, casting) and the influence of service loads (e.g. mean and residual stress)

- Damage accumulation

In addition to the standard FE solvers (ABAQUSTM, NASTRANTM, etc.) for calculating local services stresses, modern tools are used for calculating manufacturing processes (e.g. shaping, mechanical surface work hardening) and for fatigue life assessment (FEMFATTM, N-CodeTM, etc.). Alongside classic components and applications, another focal point is the analysis of structures subjected to vibrational excitation (earthquake loading, roadway surface excitation, and the like). Furthermore, analytical fatigue strength evaluations are made in compliance with the relevant guidelines (FKM, EuroCode, etc.) or according to customer-specific regulations.

Fatigue life – method development

New approaches, calculation methods and procedures are being developed for fatigue strength calculations. Such developments enable continuous improvements of the accuracy of simulation-based fatigue life assessments. Based on the results of extensive testing, new fatigue data are generated, for example, to describe local fatigue strength behaviour depending on the local manufacturing states (solidification process, local plastic deformation, etc.) and loading parameters (supporting effect, mean and residual stress, etc.). Commissioned industrial research work is another field:

- Damage-tolerant design

- Technological influences on local fatigue strength (casting, forging, surface work hardening, etc.).

- Damage accumulation

- Fracture mechanics methods

- Multiaxial fatigue etc.

- VDA ISA TISAX zertifiziert für die Labels „Informationen mit sehr hohem Schutzbedarf“, „Prototypenschutz“ und „Datenschutz“ für die Standorte Ottobrunn und Lichtenau

- ISO 14001

- ISO 9001

- DIN EN ISO/IEC 17025 for Fatigue Strength Laboratory

- DIN EN ISO/IEC 17025 für das Betriebsfestigkeitslabor - Verzeichnis der Prüfverfahren

- Accreditation Calibration Lab for Mechanical Units according to DIN EN ISO/IEC 17025

Wärtsilä Finland Oy, 2016

Gutor by Schneider Electric (Schweiz), 2015