Security is non-negotiable.

We are IABG.

As an owner-managed company, Industrieanlagen-Betriebsgesellschaft mbH is one of Europe’s leading high-tech service providers. Our mission: We design Security.

We operate independently of manufacturers and products. This independence enables us to provide neutral assessments. We identify risks, uncover vulnerabilities, and enhance transparency. Through expert consulting, we deliver increased security, making a valuable contribution to both society and industry.

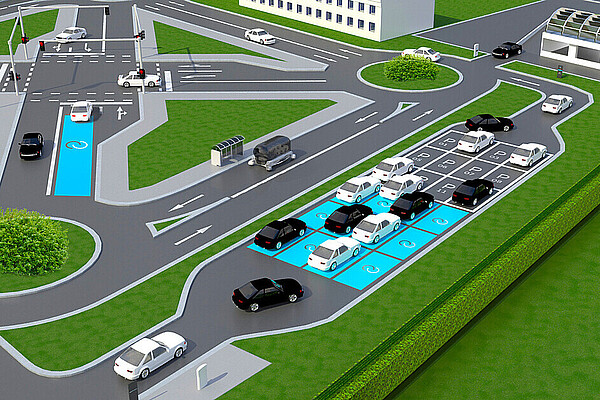

As a technology leader, we collaborate with industry partners, universities, and start-ups to test and research groundbreaking technologies. We deliver sustainable innovations that go beyond the mainstream. Our solutions are based on a comprehensive range of services and capabilities, making us the go-to partner when standard solutions fall short.

For over 60 years, clients from industry and the public sector have placed their trust in us at national and international level. With a team of 1,200 employees, we develop tailored solutions that ensure a secure future.

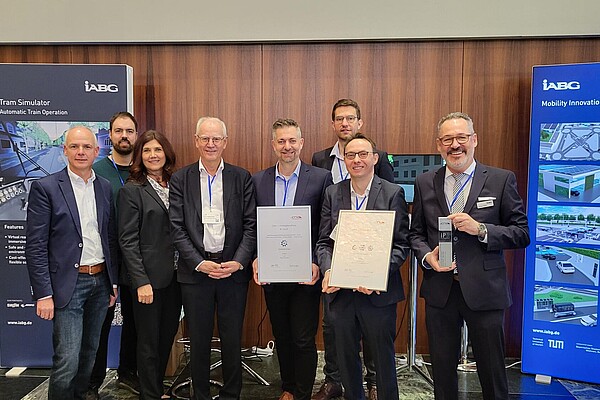

News & Stories

Dates/Events

How can we help you?

Please fill in the form and we will get in touch with you as soon as possible.