- Home

- Services

- Testing & Qualification

- Product Qualification

- Strength and Fatigue

- Home

- Services

- Testing & Qualification

- Product Qualification

- Strength and Fatigue

Strength and Fatigue

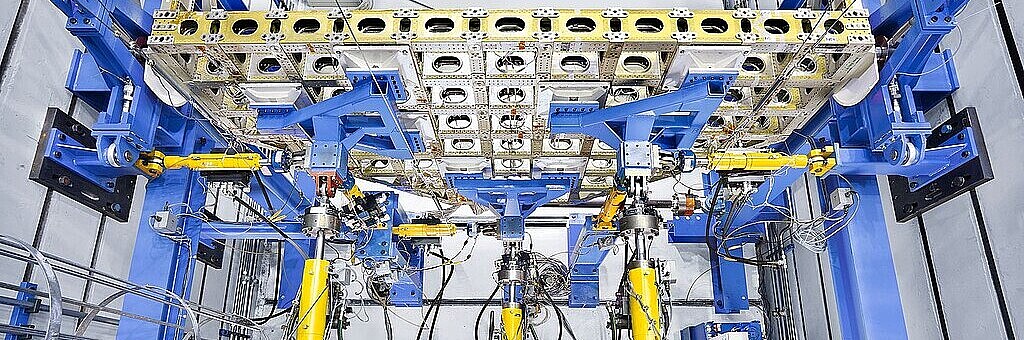

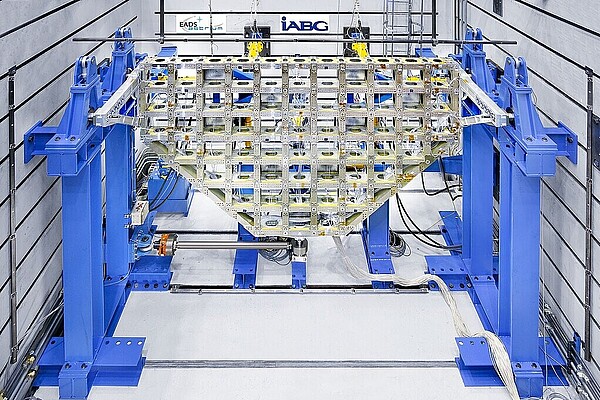

At our headquarters in Ottobrunn, we offer 5,000 m² of covered testing space (test halls) equipped with modern infrastructure, including central hydraulic, compressed air and cooling water supplies, as well as state-of-the-art safety features, including an on-site fire brigade.

On our standard and custom test benches, we test, trial and qualify entire vehicles, functional units or individual components and parts. We examine the dimensions, structural design, construction methods, materials used and behavior under defined conditions.

In addition, we develop innovative test devices. We are happy to provide individual consulting - before production, throughout the production process or for specific issues.

How can we help you?

Please fill in the form and we will get in touch with you as soon as possible.