- Home

- Industries

- Energy Technologies

- Nuclear technology

- Home

- Industries

- Energy Technologies

- Nuclear technology

Nuclear Technology - Safety through System Expertise

We have been a reliable partner to the nuclear industry for many decades. With our specialized test facilities, we qualify nuclear technology components, systems and plants in accordance with international standards such as RCC-E or IEC/IEEE 60980-344. Our test centers are accredited according to DIN EN ISO/IEC 17025 and certified according to ISO 19443 .

Our aim is to meet complex requirements with technical precision - safely, comprehensibly and in line with the application.

Our service portfolio ranges from mechanical and climatic qualifications and simulations to highly dynamic tests and special solutions such as laser decontamination or the development of special systems for dismantling. We combine in-depth expertise with state-of-the-art testing infrastructure, such as our large drop test facility in Lichtenau.

Whether it's new plants, retrofits or dismantling - we support our customers in the nuclear technology sector with a deep understanding of safety-relevant processes and regulatory requirements.

Qualification

Containers & transportation of radioactive materials

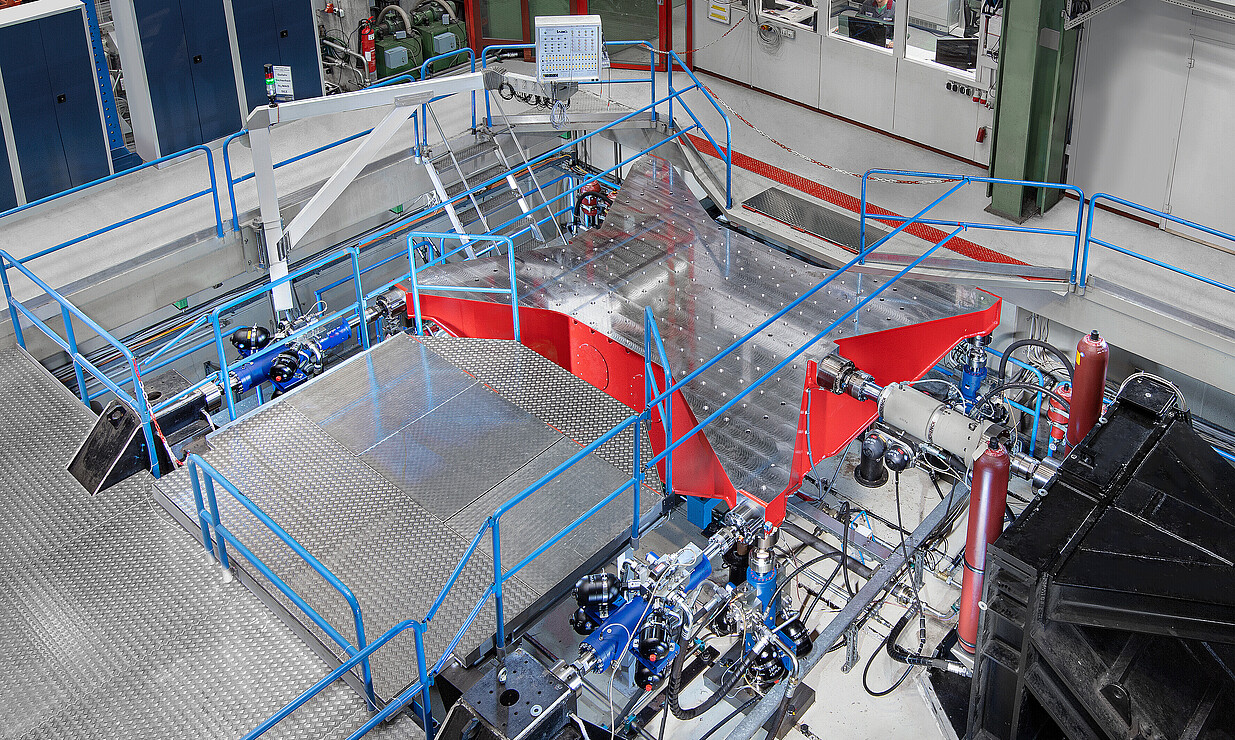

Drop tests

We conduct drop tests as part of the experimental qualification process required for nuclear regulatory approval.

More information on drop tests for nuclear energy

Impact Testing

Nuclear facilities and containers must be absolutely safe, also under extreme situations, such as targeted external impact.

More information on impact testing

Ballistic and explosive tests

We test and qualify ballistic and blast-resistant materials, right through to complete infrastructures. This is how we ensure that your products are safe.

More information on ballistic and explosive testsBurst and fire tests

We carry out various burst, drop, explosion and fire tests to check the structural integrity of components and systems. We help you secure your development.

More information on Burst and fire tests

Qualification and development

Nuclear facilities and components

Seismic qualification - vibration & shock

Seismic qualification and mechanical ageing: We offer vibration tests, shock tests, seismic tests and single- and multi-axial vibration tests (in accordance with IEC 60068-3-3, RCC-E, IEC/IEEE 60980-344 and DIN EN 60068-2-6).

More information on seismic qualificationClimatic environmental simulation

Ageing due to environmental influences: Extreme environmental influences such as altitude, humidity, temperature/heat, fast temperature changes, corrosion and chemical stress are simulated in our climate chambers and chambers.

More information on Climatic environmental simulation

Material testing and damage analysis

Understanding materials, preventing defects: Our experts examine materials, identify damage mechanisms, explain causes, recommend targeted corrective measures and develop strategies for active failure prevention – for greater reliability and longevity of your products.

More information on material testing and damage analysis

Emission monitoring

More information on emission monitoring

References

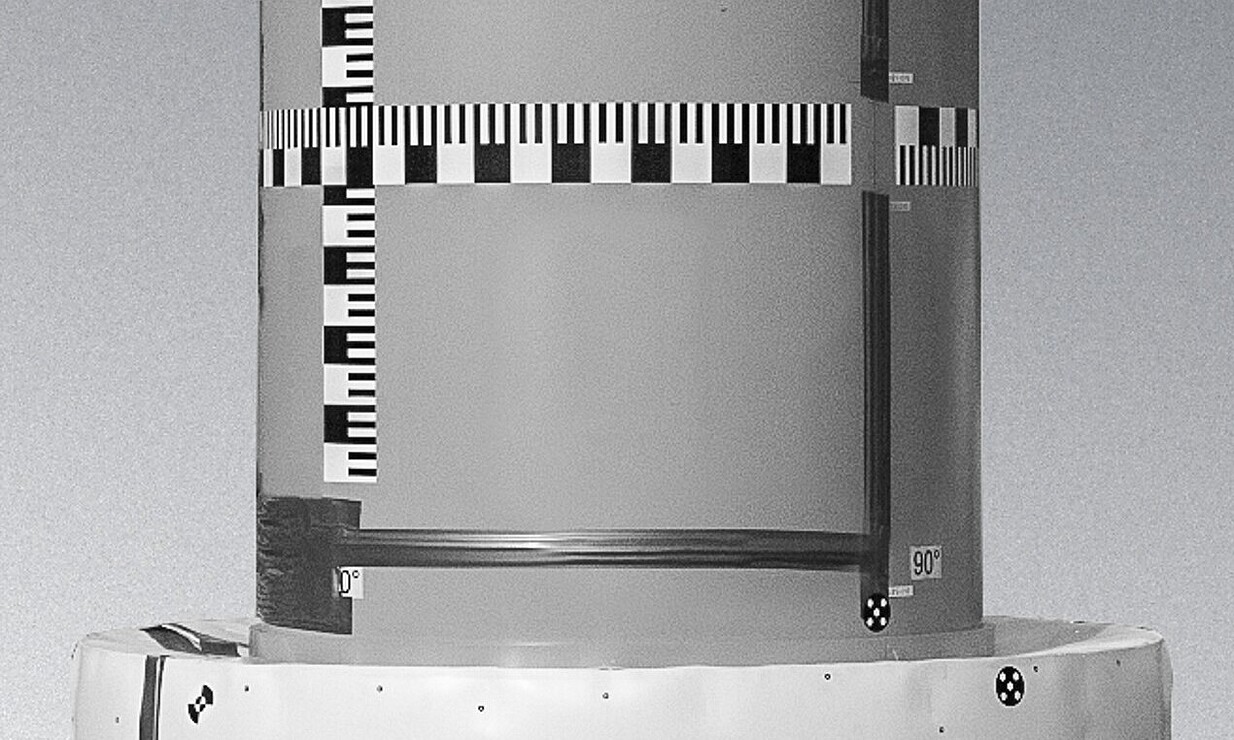

Qualification of packaging for radioactive material

The challenge: Safe transportation even under extreme conditions

An international customer needed a new packaging solution for highly radioactive materials - designed for maximum safety even under the most severe accident conditions. In addition to the strict IAEA specifications (SSR-6), additional national requirements had to be met. Proof of integrity under worst-case scenarios was particularly critical:

Impact from a great height

Extreme heat (fire exposure)

Mechanical penetration

High water pressure at depth

We were looking for an experienced partner with the necessary test infrastructure and interdisciplinary expertise - for safe and efficient approval.

Our solution: a customized test campaign

IABG developed a customized test strategy: physical tests were combined with computer simulations to assess load limits realistically and efficiently.

Drop test from a height of 9 m: proof of mechanical resistance on an unyielding impact target

Thermal test at > 800 °C: Testing the containment of radioactive substances when exposed to fire

Penetration test: 500 kg projectile on the weakest point to assess punctual resilience

Water immersion test: Tightness under 15 m water depth

The result: approval faster than planned

Thanks to the combination of simulation, targeted tests and close coordination with the approval authorities, the entire process was significantly accelerated.

✅ Planning reliability: the combination of simulations and physical tests meant that time-consuming night tests could be avoided.

✅ Efficiency: Smooth project management and coordination with authorities

✅Safety: Minimum requirements exceeded several times over

Emission monitoring

Qualification of the sampling system for emission monitoring

Requirements- Qualification of the sampling system for the exhaust air monitoring system

- Periodic inspection (WKP) of the total loss factor

- Qualification of the sampling level, adaptation of the system

Results- Identification of the relevant parameters for the sampling system

- Characterization of the system-specific emission

- Conformity with the regulations (KTA 1503.1)

- Metrological verification and acceptance of the sampling system

Solution- Metrological verification of the total loss factor

- Updating the test instructions

- Verification of the overall system after changes to the operating parameters

- Verification of the sampling level

- Adaptation & acceptance of the extraction system

Added value- "Clean & precise" procedure for metrological qualification

- Results in compliance with regulations & standards, recognized procedure

- Individual advice on the system-specific / on-site system

Dismantling Niederaichbach NPP

As part of the decommissioning of the Niederaichbach nuclear power plant, IABG supported the planning, approval and implementation of the mechanical dismantling of metallic components. We accompanied the project through all phases - from the concept review to the final clearance measurement of the affected building structures.

Initial situation

Proof of suitable dismantling technology was required for the safe and license-compliant decommissioning of the KKN. In addition to the manufacture and assembly of the systems, testing, acceptance and quality assurance documentation also had to be ensured.

Our servicesConcept and planning review of the planned dismantling technology

Preparation of a partial report in accordance with the specifications from the safety report

Carrying out preliminary tests and approval for production

Technical inspections and acceptance tests at the manufacturing plant (machine technology and control system)

Supervision of assembly and test acceptance on site at KKN

Technical dismantling support up to clearance measurement

Supplementary quality checks and documentation

Results and added valueIABG acted as an independent technical expert and supported the dismantling technology used throughout the entire course of the project - from the initial concept to the end of use. Our systematic testing and documentation work ensured a safe, regulatory-compliant dismantling process.

Development of a remote handling system (HMS)

Specialized, remote-controlled manipulator systems are indispensable for nuclear dismantling projects or operations in highly contaminated areas. On behalf of Kerntechnischer Hilfsdienst GmbH (KHG), IABG has developed a high-performance, modular remote handling system (HMS) that works reliably even under extreme environmental conditions.

Based on a standard industrial small excavator, the HMS has been fully modified to be suitable for radiation and equipped with numerous tools - from hydraulic manipulators to concrete cutters, grabs and scrap shears. It is controlled by cable or radio, and monitored and remotely controlled via a comprehensive video and sensor system.

Special technical features:

Application range: -40 °C to +55 °C, dose rate up to 100 Gy/h

Modular design for flexible tool integration

Wading capability up to 550 mm, climbing capability 29°

Protection of critical components through containment with lead shielding

Communication via redundant signal paths (LAN/WLAN)

Conformity with safety-related development standards (e.g. IEC 61508)

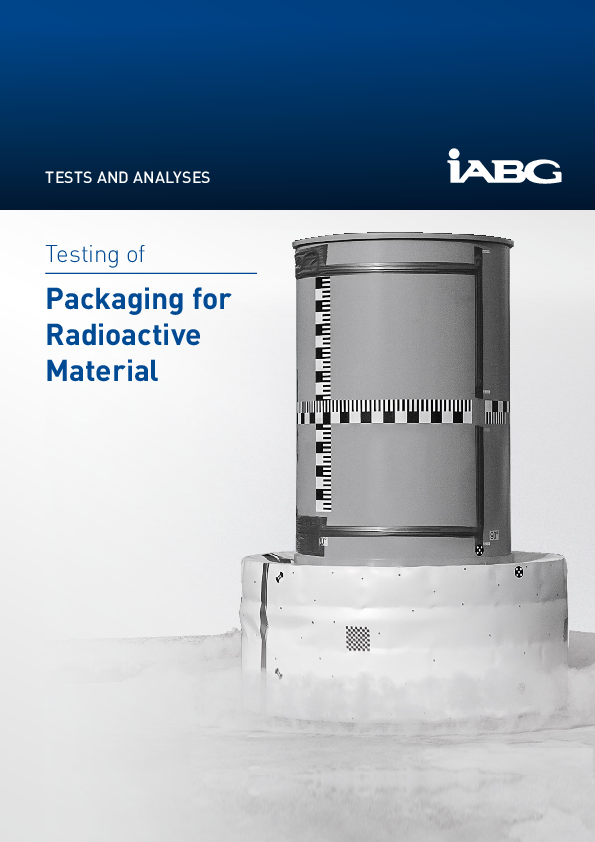

Whitepaper

PDF

/ 2 MB

Testing of

Packaging of Radioactive Material

PDF

/ 2 MB

After you have sent the form, you will receive an e-mail to verify your e-mail address.

After your confirmation, you will receive a second e-mail with the link to the requested document.

Bitte vollständig ausfüllen

Talk to us, we will be happy to advise you!

You may also be interested in these services

You may also be interested in these services

You may also be interested in these services

You may also be interested in these services

How can we help you?

Please fill in the form and we will get in touch with you as soon as possible.