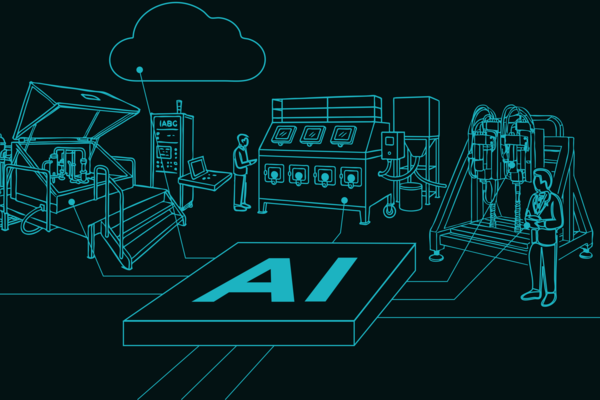

IABG Test Systems

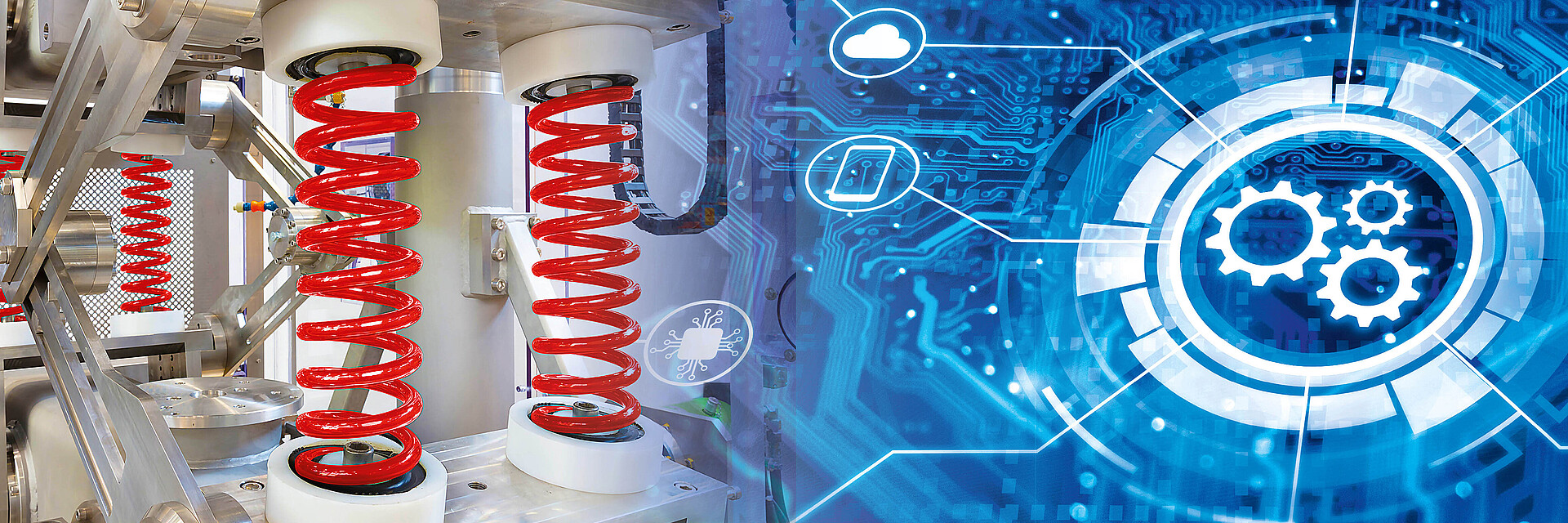

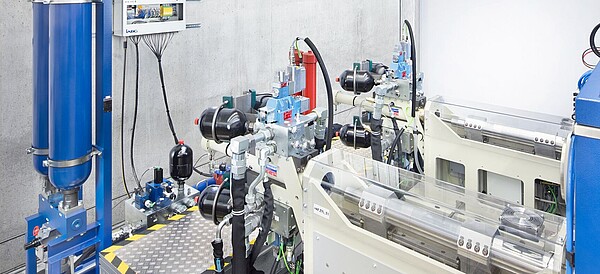

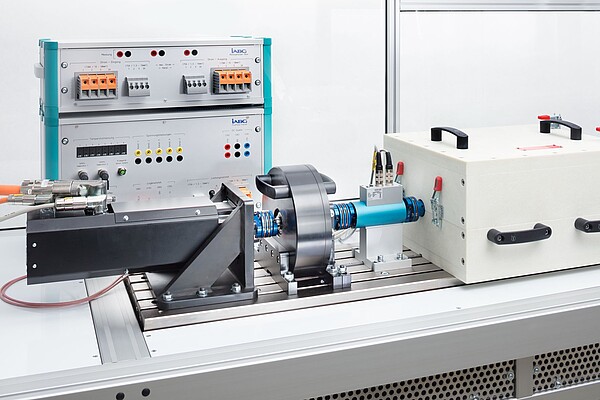

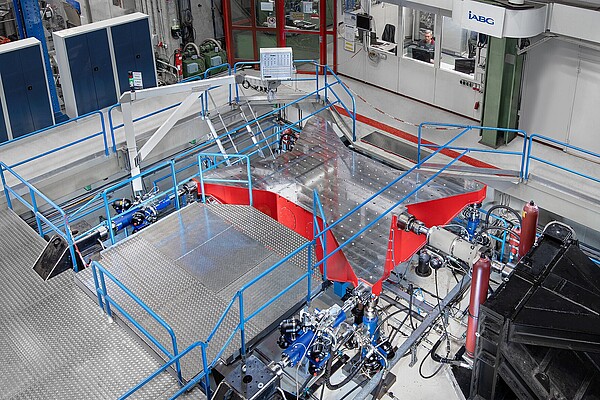

Your Expert Partner for Test Benches

We support you with our expertise, tailored to your needs, through every phase of your project. This includes:

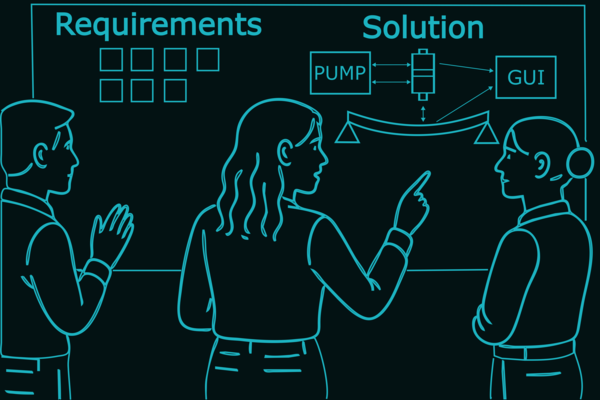

Consulting Services

Assisting with the specification of your test system, co-developing hardware and software architectures or defining appropriate safety concepts.Service Provision

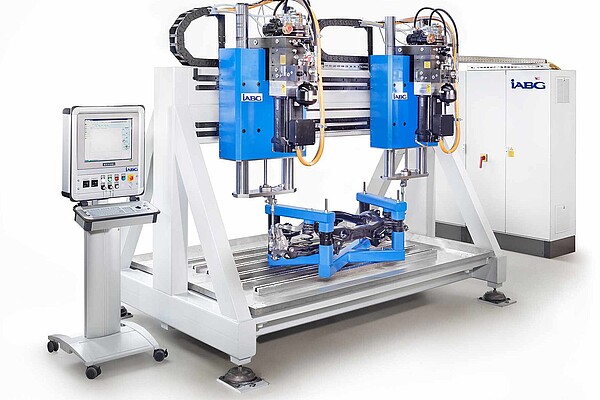

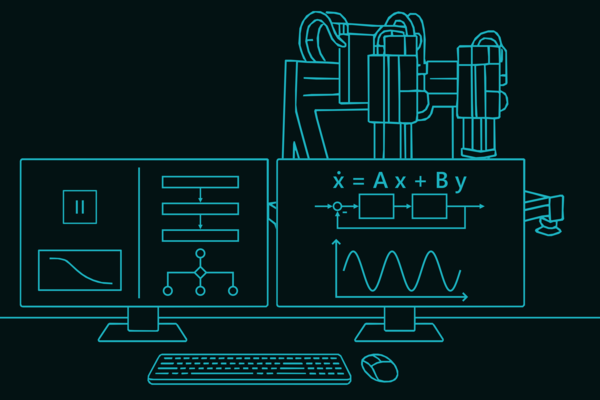

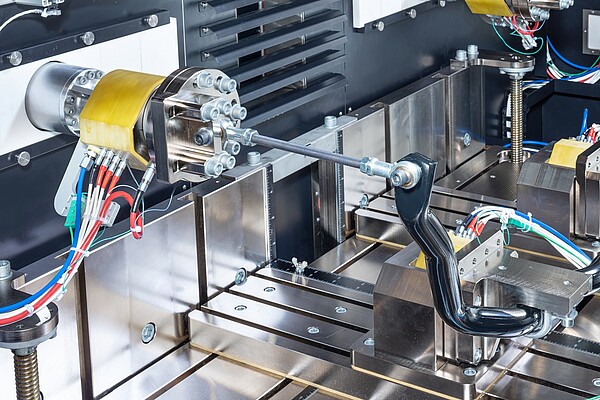

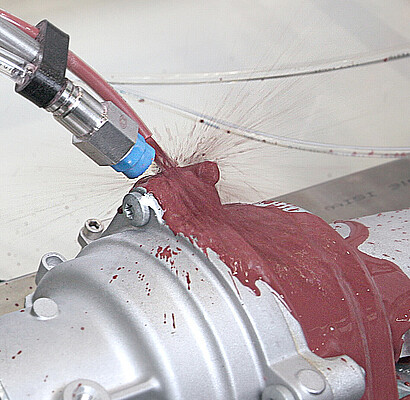

Conducting feasibility analyses or managing specific tasks such as mechanical, electrical or hydraulic design, software development and test automation.Development Partner

Supporting the development, evaluation and validation of concepts.Turnkey Solutions

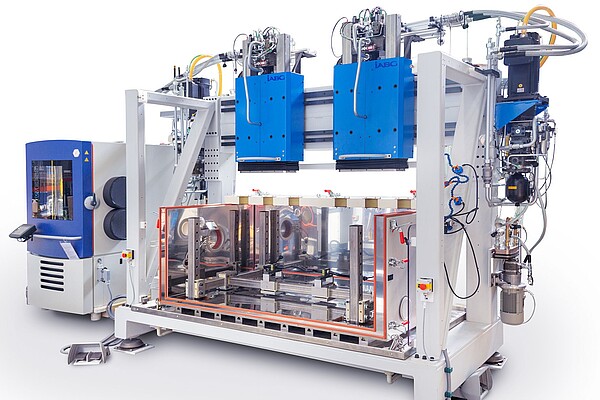

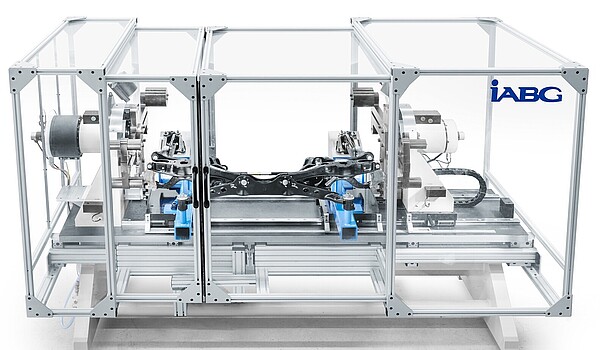

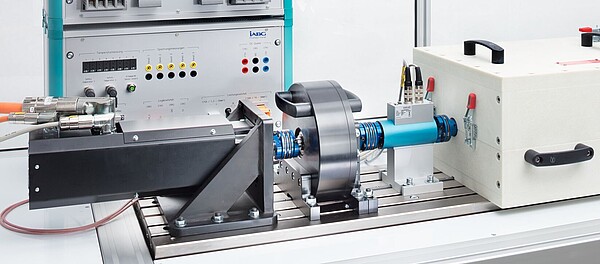

Delivering complete test benches and modernizing your existing facilities.

Together, we identify the optimal solution for your specific challenge—focusing on cost-effectiveness, technical excellence and the most suitable working model for your needs. We work closely with you, prioritizing transparent risk and project management.