Your Key Advantages at a Glance

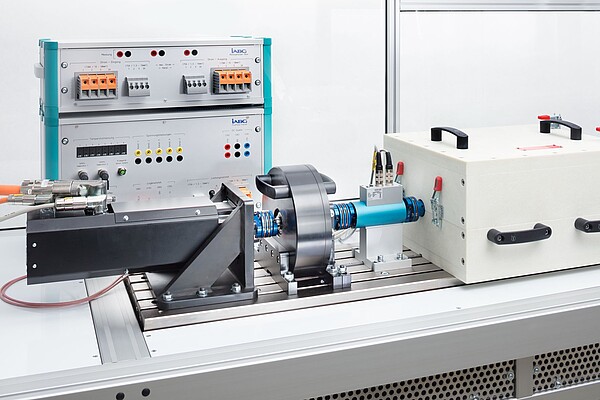

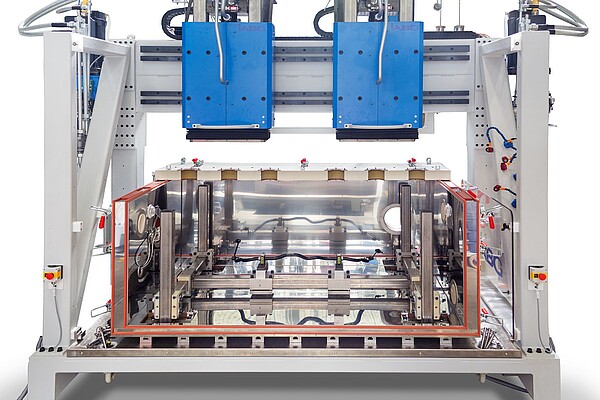

✅ Exact and automated media application for precise test results

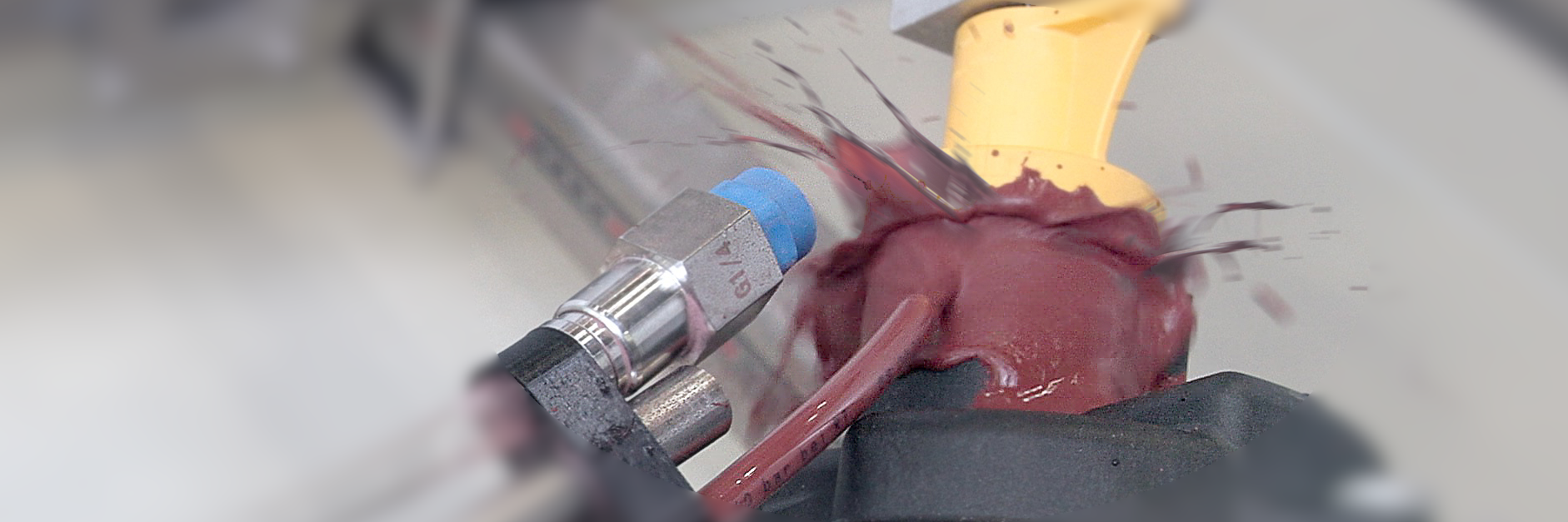

✅ Wide range of applications with China Dust, Turkish Grid and salt water

✅ Repeatable and reproducible tests under controlled conditions

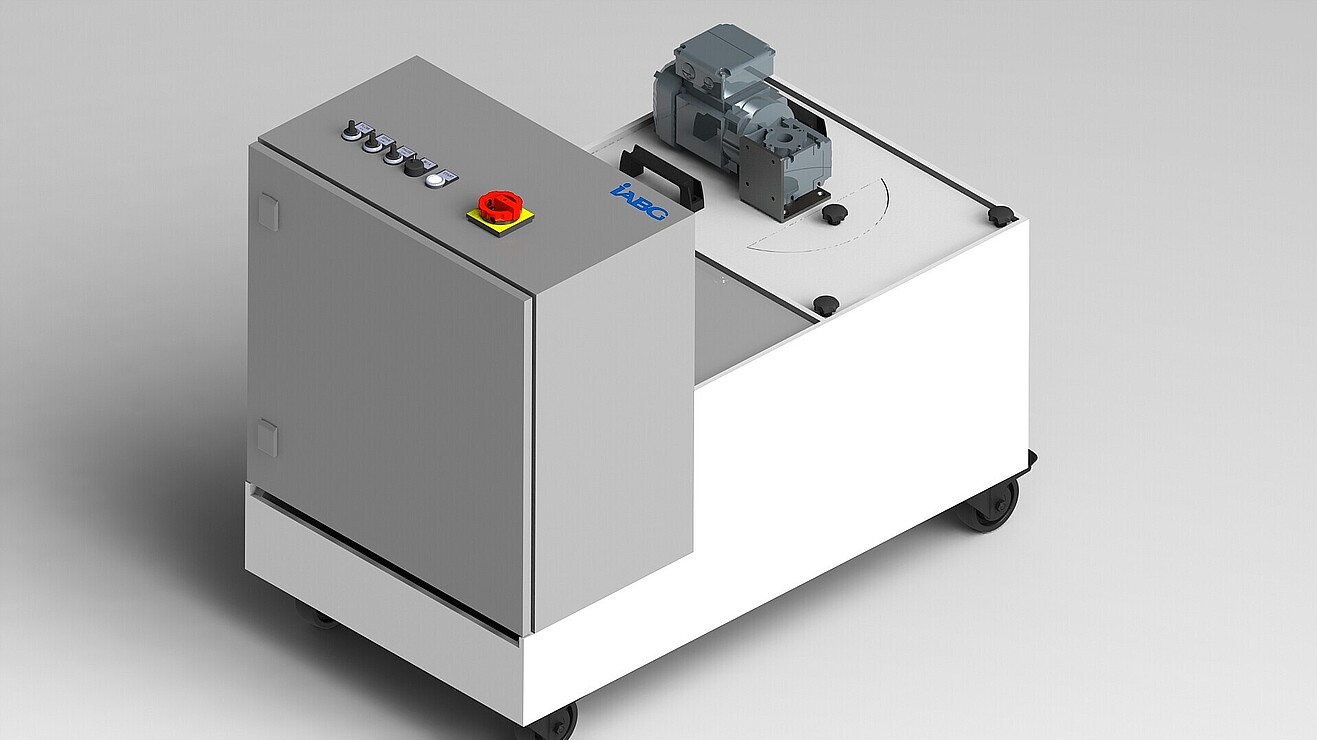

✅ Low maintenance and high reliability

✅ Flexibility and integration into various test scenarios

✅ Efficient workflows thanks to automated processes