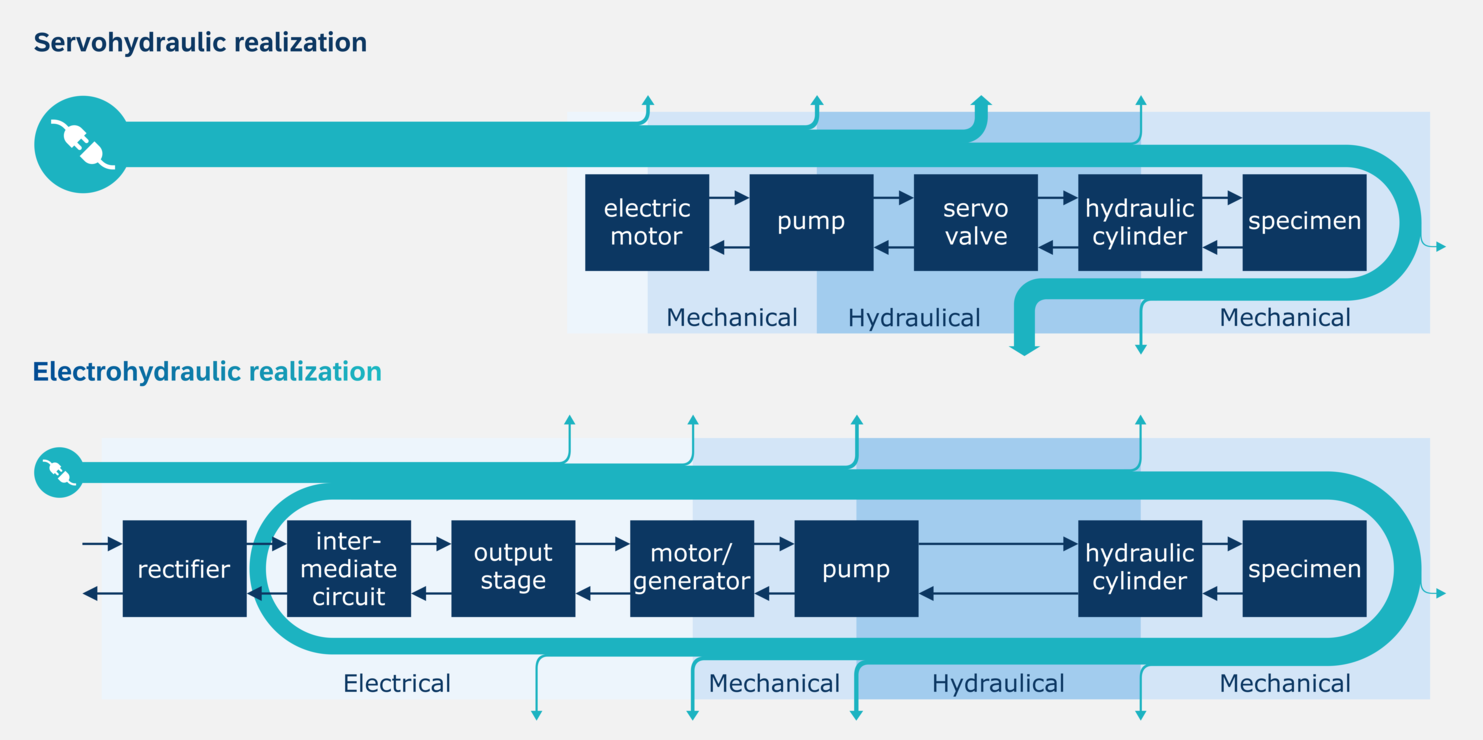

- Demand-driven force-pressure coupling: By directly controlling the pump, the hydraulic pressure is generated in proportion to the current power requirement. In contrast to classic servo hydraulics, this eliminates the energy-destroying throttling of "excess" pressure.

- Electric braking: During the braking processes, the kinetic energy of the test object is converted into electrical energy. This means that, in contrast to classic servo hydraulics, no additional drive power is required to apply braking forces, which significantly increases the overall efficiency of the system.

- Intermediate storage: The energy recuperated during braking is stored in intermediate circuit capacitors and is available again for subsequent load cycles.

- Home

- Services

- Testing & Qualification

- Development & Construction of Test Systems

- Electrohydraulic Drives

- Home

- Services

- Testing & Qualification

- Development & Construction of Test Systems

- Electrohydraulic Drives

Electrohydraulic Drives

Electrohydraulic drive technology is a powerful and future-proof alternative to conventional servohydraulic systems. It combines the high power density of hydraulics with the energy efficiency of electric drives and thus combines low operating costs with high dynamics, low space requirements and high force levels. The drives also impress with maximum future-proofing: thanks to their modular design, test benches can be adapted flexibly, quickly and cost-effectively to changing test requirements - for example by simply replacing the hydraulic cylinder. As the technology only requires a power connection, it is particularly flexible to use, for example when changing locations or relocating plants, and eliminates the need for costly infrastructure investments. In addition, the compact design enables optimum use of space.

Energy-efficient, sustainable and environmentally friendly - closed hydraulic systems for maximum operational safety

The use of electrohydraulic drives significantly reduces energy consumption, which is directly reflected in lower operating costs and a better environmental footprint. Our electrohydraulic systems work with semi-open hydraulic circuits, which minimizes leakages. They therefore meet the highest environmental and safety standards.

Low-maintenance and modular - self-sufficient drive solutions for continuous operation

Our electrohydraulic drives are specially designed for low-maintenance continuous operation and therefore guarantee maximum availability. Through consistent technical modularization, we use the advantages of this drive technology both in standard machines and in individually designed test systems. The drive technology can be used for both linear and rotary movements - with minimal integration effort.

Your advantages at a glance

✅Energy-efficient drive solution

Reduce your operating costs sustainably thanks to energy-efficient drive technology.

✅ Compact system design

Thanks to their high power density, our drives require minimal installation space. This makes them ideal for mobile and flexible applications.

✅ Minimized maintenance effort

Compared to servo-hydraulic systems, electrohydraulics require significantly less maintenance. This results in minimum downtime and maximum availability.

✅ Plug-and-run

Fast commissioning and stand-alone functionality enable uncomplicated integration into the existing infrastructure.

Efficient, dynamic and energy-saving

How the electrohydraulics work

In electrohydraulic drive systems, instead of conventional servohydraulic drives, the hydraulic fluid is not controlled via servo or proportional valves, but is supplied directly by a speed-controlled pump. This pump - usually a highly efficient radial piston pump - is driven by a frequency-controlled servomotor. The hydraulic cylinder is moved by actively pumping oil between the two cylinder chambers. The desired piston speed can be set precisely and with low loss by adjusting the pump speed.

Compared to classic servo hydraulics, this concept offers decisive advantages: In a conventional servo-hydraulic system, the oil flow is continuously regulated by a servo valve, which causes considerable energy losses. Unused hydraulic energy is dissipated as heat, which means that additional cooling systems are required, which in turn require energy. With electrohydraulic drive technology, these throttling losses are completely eliminated, as the volume flow is generated directly and as required. This not only significantly increases energy efficiency, but also enables recuperation: in phases in which the test object releases energy - for example when unloading after a load phase - the reflux energy can be recovered by the servomotor in generator mode, temporarily stored and used for subsequent load cycles. This not only further reduces operating costs, but also drastically reduces the need for external cooling systems.

The advantages of electrohydraulic drive technology

Discover your individual savings potential

Every testing application is unique - and the potential savings in energy and operating costs are just as individual. With our interactive energy savings calculator, you can quickly and easily find out how much you can save by using electrohydraulic drive technology in your test bay. Discover your personal savings potential.

Energy savings calculator for harmonic stimulation

User inputs:

| Test specimen | ||

| Test frequency: | Hz | |

| Amplitude of position: | mm | |

| Amplitude of test force: | kN | |

| Mean load: | kN | |

| Specimen mass: | kg | |

Cost savings

Servohydraulic energy flow

Electrohydraulic energy flow: Savings of ?? kW (by a factor of ?? more efficient than servohydraulics)

Advantages: Optimized force-pressure coupling Δ?? kW, electric braking Δ?? kW, energy storage Δ?? kWh

Future-proof.

We develop next-generation hydraulic drives for you.

How can we help you?

Please fill in the form and we will get in touch with you as soon as possible.