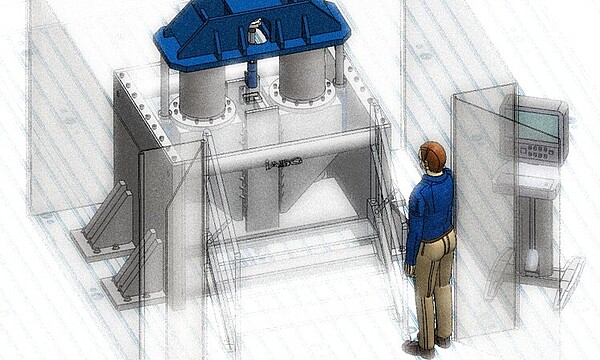

Function test benches for active dampers

Our damper function test benches make it possible to comprehensively test active damper systems under realistic conditions and defined environmental influences. This allows functions, performance and reliability to be specifically analyzed, validated and continuously improved.

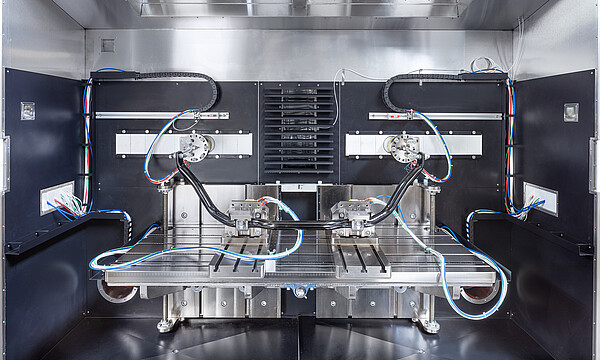

- Comprehensive function test of active damper systems

- Precise characterization of the dynamic damping behaviour

- Reliable validation of performance and service life

- Realistic simulation of critical driving scenarios

- Targeted testing under defined environmental influences