Mechanics & test specimen holder

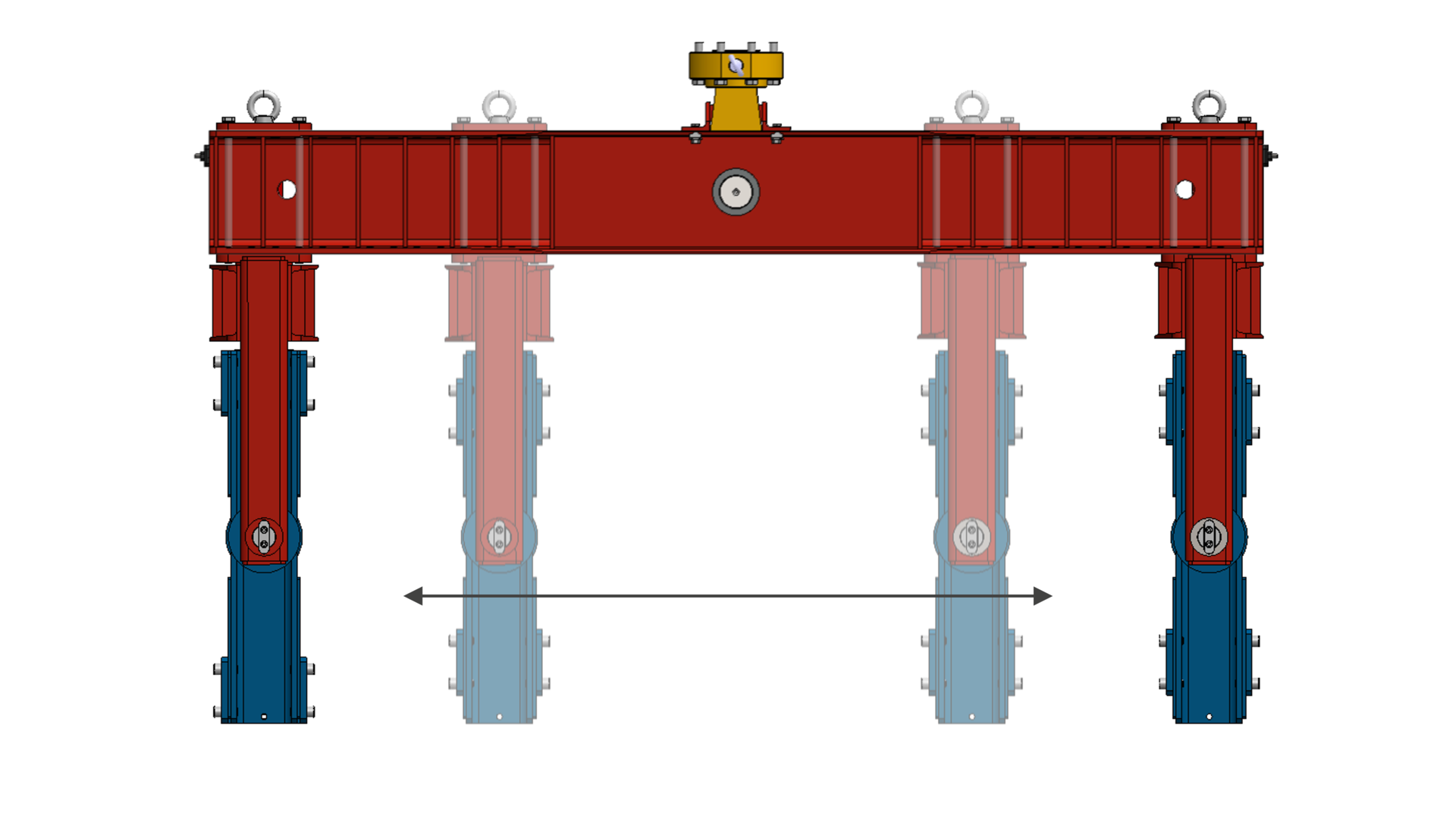

The mechanical, modular system offers the necessary flexibility to safely accommodate test specimens with different dimensions and stiffnesses.

Our newly developed test bench enables cost-efficient material testing in the early stages of rotor blade development. The innovative approach: components are already tested during development. This shortens development times and significantly reduces the effort involved in the final overall validation of the rotor blade. An innovative electro-hydraulic drive concept also ensures particularly energy-efficient and resource-saving operation."

| Customer: | Nordex SE |

| Project duration: | 2 years (2023-2025) |

| Test rig type: | Large structure 4-point bending test rig |

| Test specimens: | Wooden beams made of composite material, test specimen length 2.5 to 13 m |

| Special features: |

|

✅ Turnkey solution - test bench according to specification including individual change requests

✅ Early validation - material tests without cost-intensive full-scale tests

✅ Efficient development - thanks to improved simulation models

✅ High cost-effectiveness - energy-efficient and low-maintenance test benches

✅ Compact design - space-saving thanks to modular structure

✅ Easy integration - quick commissioning, also as a stand-alone solution

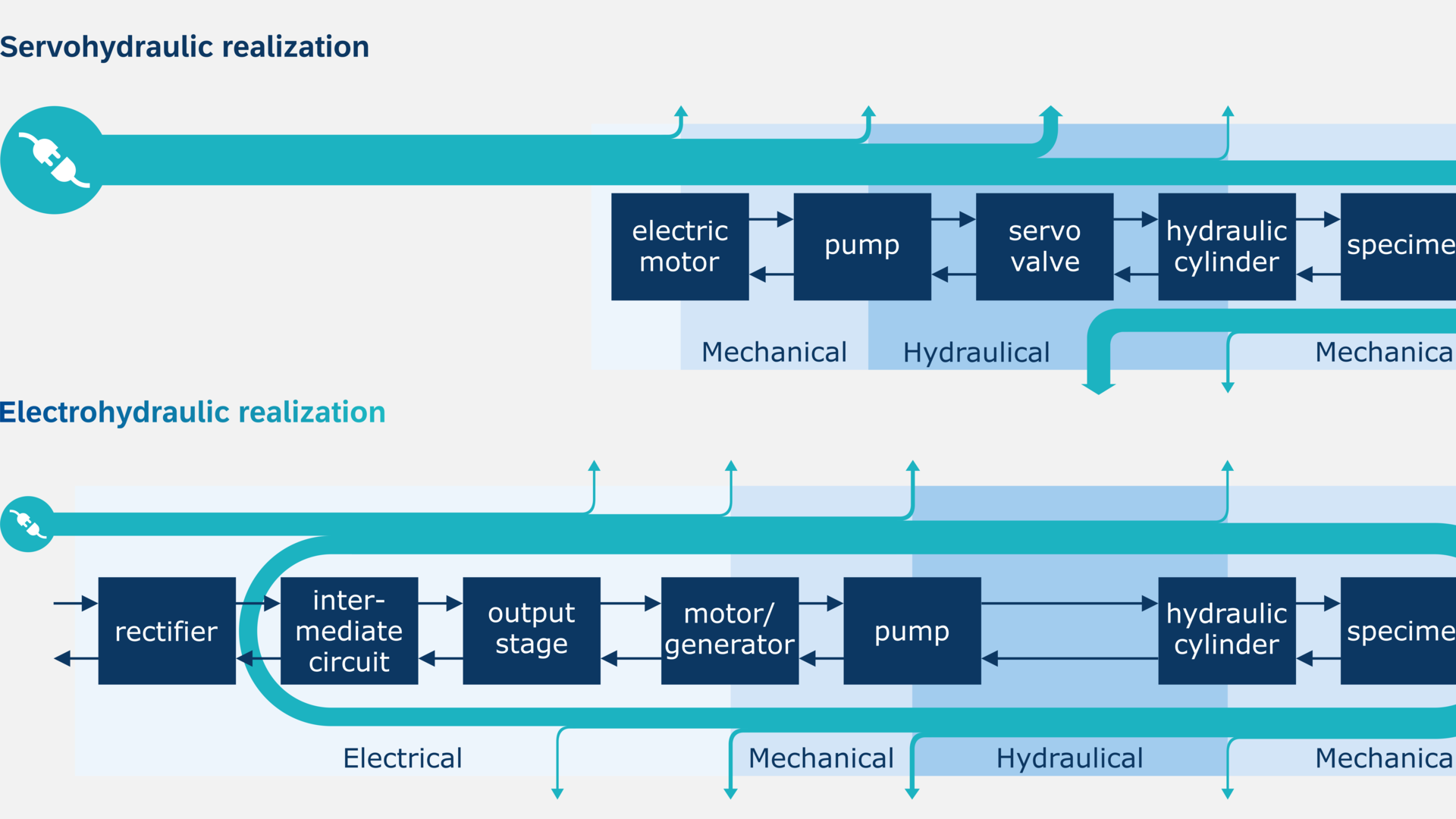

The energy-efficient, electro-hydraulic drive concept uses frequency-controlled servo pumps instead of lossy valve technology. As a result, the oil flow is controlled precisely and in line with demand.

The mechanical, modular system offers the necessary flexibility to safely accommodate test specimens with different dimensions and stiffnesses.

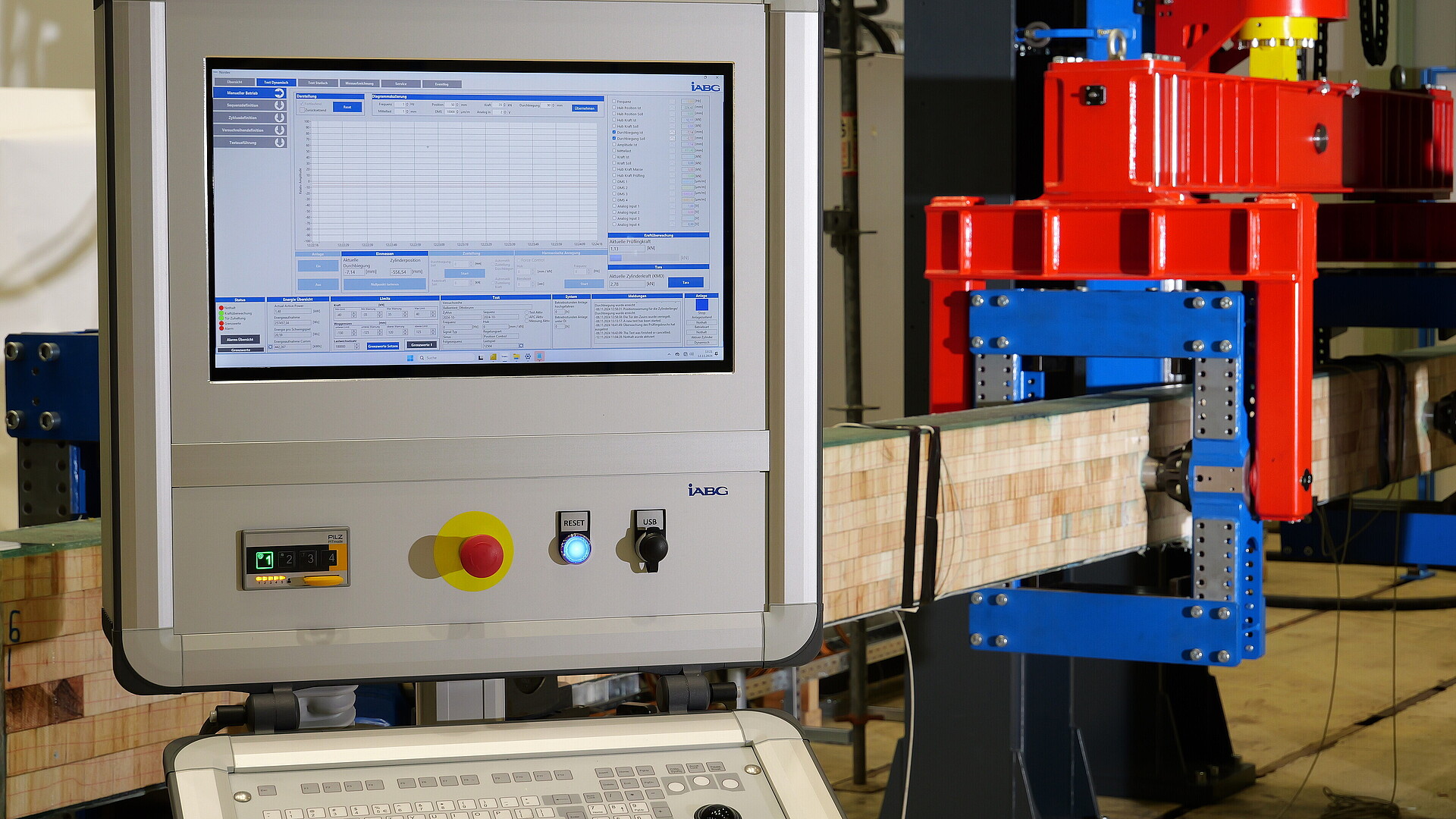

The system control is based on a powerful Beckhoff PLC with integrated safety control and is supplemented by a high-resolution, modular measuring system.

By specifically testing CFRP/CFRP test beams under realistic loads, material properties can be evaluated in a well-founded manner in early development phases and potential weak points can be identified at an early stage. The knowledge gained in the process flows directly into the further development of simulation models and design concepts. As a result, the validation effort is reduced considerably: significantly fewer full-scale tests need to be carried out and correspondingly fewer complete rotor blades need to be manufactured for testing.

The mechanical design of the test stand allows it to be adapted to a wide range of test specimen geometries thanks to two different and modular clamping concepts. Thanks to the variable drive technology, the system can be used for both static individual tests and dynamic continuous loads. This gives the test stand maximum flexibility for future test requirements.

The electro-hydraulic drive system works up to 4.4 times more efficiently than conventional servo-hydraulic solutions. By using frequency-controlled servo pumps and recuperation of deformation energy, energy consumption per load cycle can be reduced by up to 77 percent. For typical endurance tests with over one million cycles, this corresponds to savings of several thousand euros per test campaign. Over the course of a year, this results in a potential economic benefit of up to 270,000 euros.

Tip: With our interactive energy savings calculator you can easily simulate and determine your individual savings potential.

With our interactive energy savings calculator you can easily simulate and determine your individual savings potential.

Wir freuen uns auf Ihre Anfrage!

Please fill in the form and we will get in touch with you as soon as possible.