- Services

-

Materials Testing and Failure Analysis

- Macroscopy and Stereoscopy

- Metallography / Materialography

- Hardness Testing

- Scanning Electron Microscopy

- Zeiss Merlin Gemini Scanning Electron Microscope

- Chemical and Physical Materials Analyses

- Non-destructive Testing

- X-Ray Inspection Systems

- Environmental Simulation

- Additive Manufacturing

- Powder characterization procedure PowderGenetics®

- Residual Stress Analysis

-

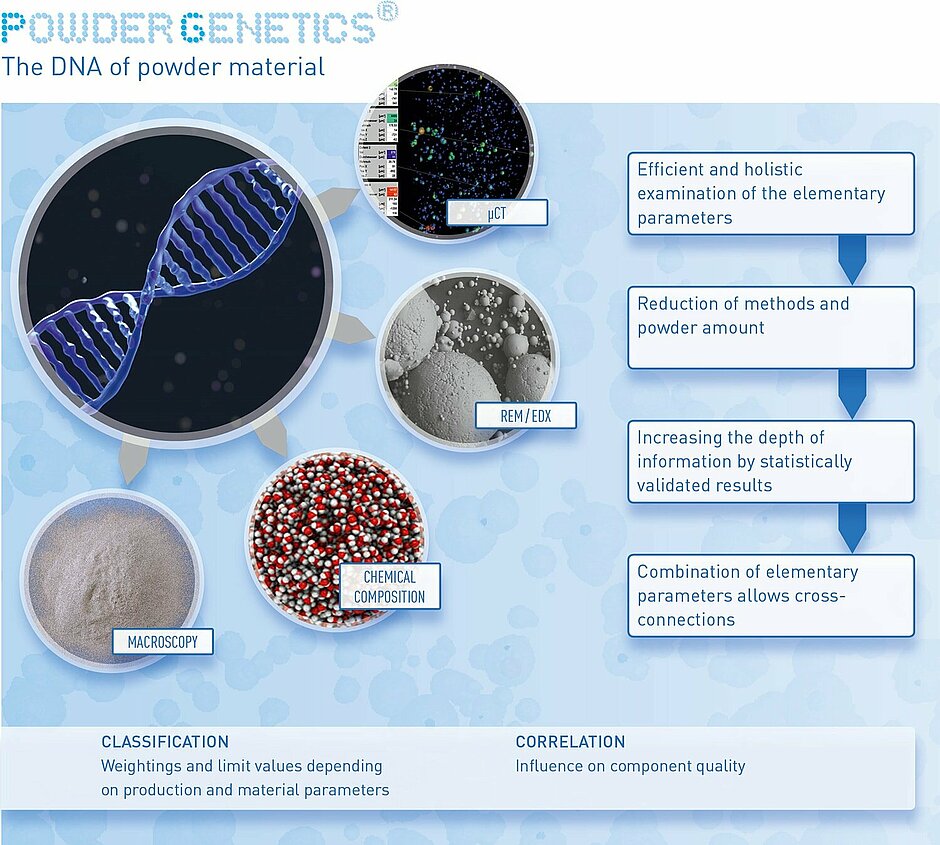

Powder characterization procedure PowderGenetics®

The DNA of powder material

Powder characterization procedure PowderGenetics®

Powder Genetics® is an IABG invented powder characterization procedure for metal and ceramic powder material. With the performance of four investigation methods at a small amount of powder (20 – 50g), elementary powder properties are both qualitatively and quantitatively obtained.

All methods are interdependent which allows cross connections of characteristic properties for correlation purposes.

Powder Genetics® is the holistic approach of a sustainable powder characterization due to the reliability of the results and the transferability to the manufacturing process. Included within an AM data base, Powder Genetics® is the foundation for optimization, correlation and stabilization purposes within the value chain of additive manufacturing.

By activating this video the external provider might be able to collect user specific data by activating this content. For more information please check out our data protection.

Powder characterisation for AM-Products

| Method | Characteristics | Description | Remark |

|---|---|---|---|

| Macroscopic investigation | Rough estimation of non-acceptable features as obvious discolouration and humidity | 3D-information pure qualitative efficient | Possibility to refuse powder material in an early stage |

| Chemical analysis | |||

| a) X-ray fluorescence | Chemical composition | Full scale spectra of contained elements, qualitative and quantitative information | Possibility to refuse powder material in an early stage – due to strong acceptance criteria |

| b) Carrier gas hot extraction | Determination of elements H, N, O, C, S | ||

| c) Colourmetric Karl Fischer titration | Content of water | ||

| SEM-investigation | Topography, Morphology, Contamination | 2D-information, qualitative | CT-scan resolution and evaluation criteria for sphericity are gained by the results of SEM investigation |

| Computed tomography | Particle size and distribution, morphology, surface area, particle volume, hollow spaces, higher dense particle | 3D-information of elemental properties, quantitative | Statistically verified due to a high amount of scanned particles (10e5) |

Macroscopic investigation

The visual inspection allows a fast and very efficient approach of detecting rough abnormalities within

the powder material. Following listed features are compared to specified characteristics for an efficient

approach of evaluation.

- Discolouration

- Humidity

- Coarseness of grains

- Contamination

Chemical Analysis

![[Translate to English:] PowderGenetics - Chemische Analyse](/fileadmin/_processed_/5/0/csm_PowderGenetics_chemische-Analyse_b8cdf86748.jpg)

The chemical composition of powder material forms an essential aspect of powder characterization. The content of specified elements, impurities, contamination and the content of highly reactive light elements play a decisive role for the usability of a powder material. The results of the investigation are evaluated with a target/actual comparison as a quality assurance measurement.

In case of a non-conformance, the powder material might be refused. Due to cost and time saving this approach is a very efficient procedure. Also for mixed or refurbished powder material the chemical analysis is essential regarding the usability of powder material for distinct purposes.

- Determination of chemical composition for specified elements

- Content of water

- Content of reactive elements as H, N, O, C, S

- Rough contamination

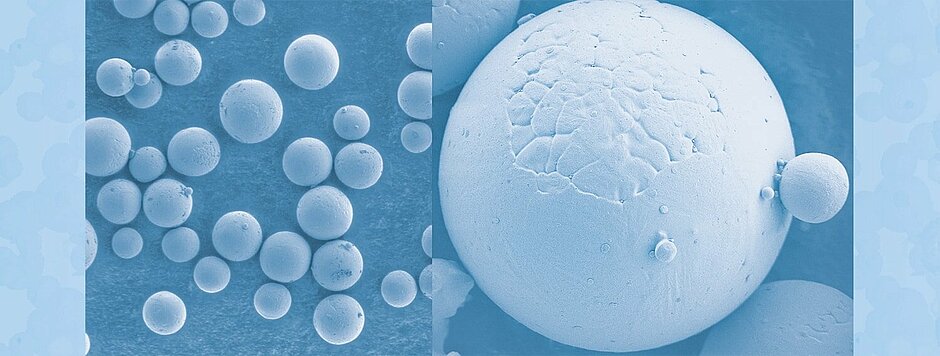

Scanning electron microscopy

By the means of scanning electron microscopy, a sample of about 500 powder particles becomes investigated for gaining qualitative results. The information about surface structures, sub- and de-shaped particles combined with the size distribution are important to estimate the flowability behavior of powder material. Furthermore the qualitative results are evaluated as input and scan data for the computed tomography.

The following features are obtained qualitatively:

- Morphology

- Topography

- Contamination

- Size distribution

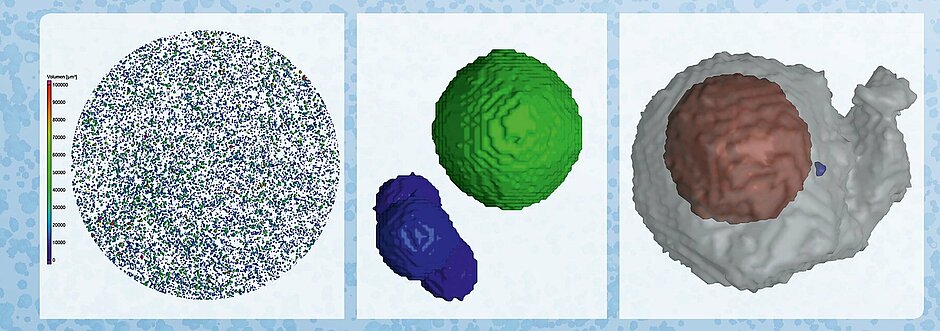

Computertomografie

In einer Kapselprobe befinden sich mehr als 10e5 Partikel, die ohne Agglomerate und Konglomerate, vereinzelt dargestellt vorliegen. Die Probenerstellung hat eine hohe Reproduzierbarkeit und erfolgt frei von Artefakten in einer gleichbleibenden Geometrie. Ein hochauflösender Scan mit einer Voxelgröße von bis zu 500 nm ermöglicht die dreidimensionale Betrachtung von elementaren Partikelmerkmalen. Analog zu den REM-Analyseergebnissen erfolgt eine statistisch abgesicherte Auswertung der Partikeleigenschaften mit höchstmöglicher Informationstiefe.

Die Bewertung umfasst einen Soll- / Ist-Vergleich der nachfolgend aufgeführten elementaren Kenngrößen analog zu spezifizierten Vorgaben.

- Partikelgröße

- Partikelgrößenverteilung

- Morphologie

- Verteilung der morphologischen Merkmale

- Fläche

- Partikelvolumen

- Hohlräume

- Höherdichte Partikel (HDP)

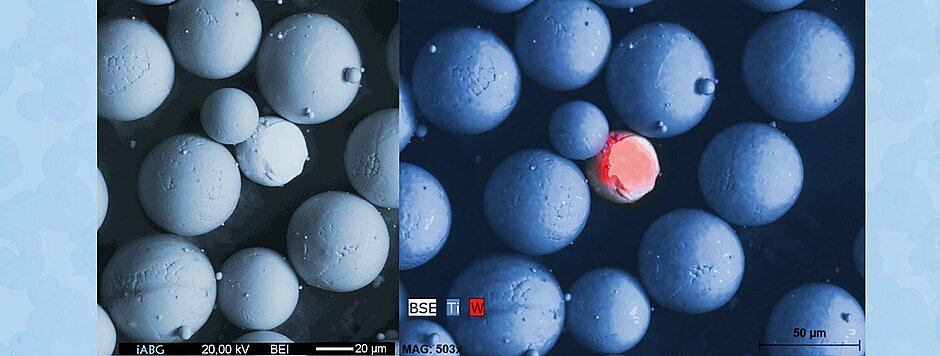

Optional: Contamination analysis

Contaminations of elements below the detection limit of the chemical analysis or which are in the material specification of the powder material can be determined qualitatively and quantitatively in sub-ppm-range.

Plastics, lower and higher dense materials as well as different powders can be analysed. The amount of contamination is determined by computed tomography or gravimetricly. The contamination will be isolated from the powder and analysed by light optical or scanning electron microscopy.

![[Translate to English:] Makroskopie und Stereoskopie](/fileadmin/_processed_/e/6/csm_Makro-Stereoskopie_400x200_95153c2a31.jpg)

![[Translate to English:] Rasterelektronenmikroskop Zeiss Merlin Gemini](/fileadmin/_processed_/5/f/csm_Rasterelektronenmikro_Zeiss_400x200_76ab1dd2d3.jpg)

![[Translate to English:] Umweltsimulation & Schadensanalyse](/fileadmin/_processed_/2/5/csm_Umweltsimulation-Schadensanalyse_400x200_43cde76a55.jpg)

![[Translate to English:] Metallografie / Materialografie](/fileadmin/_processed_/c/9/csm_Meallografie-Materialografie_400x200_8cc43a1051.jpg)

![[Translate to English:] Chemische und physikalische Werkstoffanalysen](/fileadmin/_processed_/a/b/csm_Werkstoffanalyse_400x200_09062cf421.jpg)

![[Translate to English:] Additive Fertigung](/fileadmin/_processed_/5/1/csm_Additive-Fertigung_400x200_44855c2ef5.jpg)

![[Translate to English:] Härteprüfung](/fileadmin/_processed_/9/4/csm_Haertepruefung_400x200_73a4c4559b.jpg)

![[Translate to English:] Zerstörungsfreie Prüfverfahren](/fileadmin/_processed_/6/1/csm_Zerstoerungsf_Pruefverfahren_400x200_aafe80351c.jpg)

![[Translate to English:] Pulvercharakterisierungsverfahren PowderGenetics®](/fileadmin/_processed_/c/d/csm_PowderGenetics_400x200_ab495fe74c.jpg)

![[Translate to English:] Rasterelektronenmikroskopie (REM)](/fileadmin/_processed_/f/7/csm_REM_400x200_f58e0f4e54.jpg)

![[Translate to English:] Röntgeninspektionssysteme](/fileadmin/_processed_/d/3/csm_Roentgeninspektionssystem_400x200_b3d223c6a9.jpg)

![[Translate to English:] Eigenspannungsmessung](/fileadmin/_processed_/e/b/csm_Eigenspannungsmessung_400x200_0c75787702.jpg)