- Services

-

Consulting

- Government Agency Networks

- Procurement support and utilisation

- Cyber security

- Professional Mobile Radio for Public Safety Organisations

- Implementation of management systems

- Human factors & ergonomics

- Industry 4.0 / Internet of Things

- Control and situation centres

- Mobility services

- Programme Support

- Dismantling of nuclear facilities

- Safety and functional reliability

- Safety Medical Technology Sector

- Safety Defence Sector

- Safety Automotive

- Satellite navigation (PRS)

- Safe City

- Security Policy

- Structural monitoring, inspection and analysis

- Environmental service

- IT Public procurement management

-

Safety Automotive

Safety Automotive

Safely into the future of automated driving

The human interaction and integration with technology is reaching new levels – highly automated and fully automated driving has now become the mid-term goal of all automobile manufacturers.

Dependability plays a major role here. Dependability addresses different system characteristics including the safety and availability of a system. The integration of digitised systems makes demands on safety (the effect of technology on humans and the environment) and security (the effect of humans and the environment on technology).

Safety involves avoiding inacceptable risks or the physical damage of a system and its components, protecting the environment from harm and preventing failure of safety-critical processes through the test objects. Safety, therefore, goes beyond purely functional safety and also encompasses, for example, the electrical safety of the power train or the chemical safety of the battery.

Security is concerned with crime prevention, i.e. measures to prevent unauthorised manipulation of a system, a machine or a network environment. This is more comprehensive than straight Cyber Security. For example, an ADAS radar can be influenced by jamming and spoofing.

Our holistic approach includes system availability as well as Human Factors. We apply an “all hazards” policy in our projects which can be summed up with the abbreviation TAHOI 1

We support automotive manufacturers and suppliers in achieving their goal of developing products with maximum safety and security, and bringing them to market. To this end we provide our customers with our expertise and experience.

Our Services / Solutions

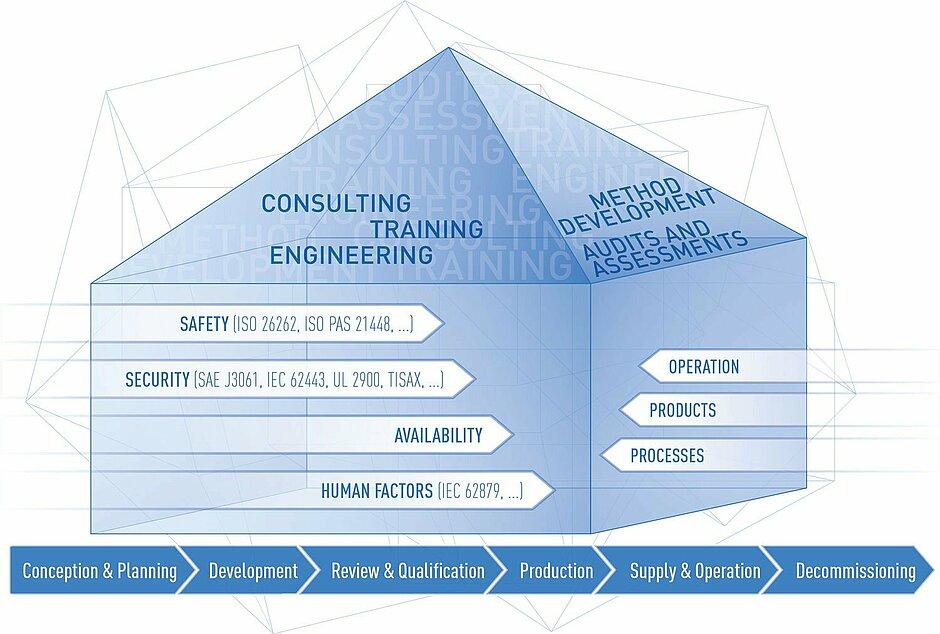

Consulting • Training • Engineering • Method Development • Audits and Assessments

- For processes, products and safe operation

- Considering the aspects of Safety, Security, Availability and Human Factors

- Across all phases of the life cycle and all work products

- Including analyses, requirements management, validation and verification

We work in compliance with the following standards and regulations (excerpt):

- ISO 26262

- SAE J3061

- UL 2900

- IEC 62443

- TISAX

- ISO PAS 21448

- IEC 62879.

Our References – Three Sample Customer Projects

Security Concepts and Safety Analyses

Every development project includes safety analyses. After conducting a hazard and risk analysis, we define the safety goals of a system and then develop functional (FSC) and technical safety concepts (TSC). Depending on the required standards, these are checked by means of FTA (Fault Tree Analysis) and/or FMEDA (Failure Modes Effects and Diagnostic Analysis). We help customers perform these safety analyses and process the results. Through close cooperation with our customers we provide “on-the-job training” to make those working on the project familiar with the analyses. This improves both the quality of the development and the communication of the results to the end customer.

Introducing Functional Safety into the Development Project of a Supplier

Even established, large companies with own successful in-house developments often find it a challenge to integrate all the different functional safety requirements in their development projects and processes. The requirements of ISO 26262 apply to the entire development cycle and demand the creation of new project roles, for instance the designation of a Functional Safety Manager. Development teams often have difficulties meeting all the requirements for proof and documentation.

This where we come in to support the customer’s safety manager and executives by introducing and implementing fitting changes to the development processes to establish a safety culture in the company and ensure compliance with the functional safety requirements for the project. In this respect, we pay special attention to avoiding isolated solutions. We train the project team through joint reviews of project-specific safety artefacts. If requested, we set up an interface to the end customer and help in the communication of project progress.

Preparing an Automotive SPICE Assessment

Automotive SPICE is an established framework for assessing the performance of development processes for systems in the automotive industry. The process assessment and project assessment models describe the conditions recognised worldwide as best practices. OEMs and suppliers agree on development compliant to Automotive SPICE as quality objectives in the project; these are checked by means of Automotive SPICE assessments. We provide hands-on support for the introduction of Automotive SPICE by qualifying those responsible in the relevant Automotive SPICE processes (extended VDA scope). The first step is to identify gaps in the development process and check the maturity of work products. In workshops we review concepts and strategies with the project team. Internal guidelines are developed in parallel and applied directly to the project; training and coaching are planned and delivered as required specifically for each project.

Prerequisite for successful preparation of an assessment is long-term, close cooperation with the quality management on the one hand and with the development team on the other.

1Technical failures, Acts of god, Human errors, Organisational failures, Intentional acts (TAHOI)