Product qualification • RTCA/DO-160 testing

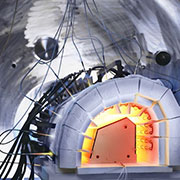

The high standards that technical products are held to regarding reliability, robustness, durability and compliance with statutory provisions require sophisticated test procedures. Not only is it necessary to confirm the functionality of these aircraft, but it is also essential to evaluate the behaviour of a product while subjected to environmental influences during the real product life cycle. Our teams of experienced experts and our powerful, modern facilities can perform any environmental test for a wide range of applications.

All tests comply with national and international testing standards, e.g. MIL-STD 810, RTCA/DO-160:

- VDA ISA TISAX zertifiziert für die Labels „Informationen mit sehr hohem Schutzbedarf“, „Prototypenschutz“ und „Datenschutz“ für die Standorte Ottobrunn und Lichtenau

- ISO 14001

- ISO 9001

- DIN EN ISO/IEC 17025 for Fatigue Strength Laboratory

- DIN EN ISO/IEC 17025 für das Betriebsfestigkeitslabor - Verzeichnis der Prüfverfahren

- ISO 9001 (Location Dresden)

- EN 9100

- EN 9100, AS910, JISQ 9100

- Kopter Group AG Industrial Maturity Management Audit, 2020

- Airbus S.A.S., 2010, 2011, 2017

- Airbus Helicopters, 2015

- Eurocopter, 2012

- Bombardier Aerospace, 2012

- EADS Elbe Flugzeugwerke GmbH, 2011

- ASCO Industries N.V., 2011

- AREVA NP GmbH, 2007

- Rolls-Royce Deutschland Ltd & Co KG, 2007

- MTU Aero Engines, 2004

- Patria Finavicomp Oy (Finnland), 2004

- Airbus Deutschland GmbH, 2002

- Verizon, Underwriters Laboratories Inc. (USA) 2002