- Business Fields

- Automotive

-

Springs

- Fatigue strength of axle springs

- Fatigue strength of valve springs

- Corrosion Spring Testing Machine (CSTM)

- Dry Spring Testing Machine (DSTM)

- Valve Spring Testing Machine (VSTM)

- Variable Test Rig for Resilient Components (VTRC)

- Grit Impact Simulator Machine (GISM)

- Rotating Bending Test Machines (RBTM)

- Large Spring Testing Machine (LSTM)

- Spring Coil Test Machine (SCTM)

-

Grit Impact Simulator Machine (GISM)

Grit Impact Simulator Machine (GISM)

With the IABG Grit Impact Simulator Machine it is possible to create stone impact damage to components in a defined and reproducible manner. The type and amount of discharge material and impact velocity is continuously variable, within certain limits. It is guaranteed that every single particle of the selected discharge material – regardless of its shape, size and weight will have the same defined speed.

The two simulators developed by IABG are among other things designed to test suspension springs, stabilizer bars, dampers, axle components, motor vehicle or rail vehicle fronts, car body parts, fuel tanks, transmission housings, oil pans, windscreens and axles. They are also suitable for the simulation of hail fall on wind power rotor blade tips or solar panels.

Advantages of the IABG Grit Impact Simulator

- The velocity of the individual particles in the discharge material is independent of weight, size and shape

- Therefore the test is consistent and accurately reproducible

- The method is equivalent to the standards DIN 20567 and SAE J400

- High Variation of the area to be targeted

- Test specimens can be rotated throughout the procedure producing a regular damage pattern

- Large selection of discharge material (gravel, chippings, stone shards, sand or balls of various materials)

- Simple operation without the need for extensive training

- Reliable and low maintenance

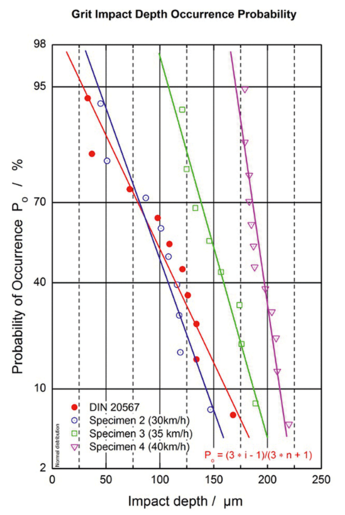

Verification of the reproducibility of standards DIN 20567 and SAE J400

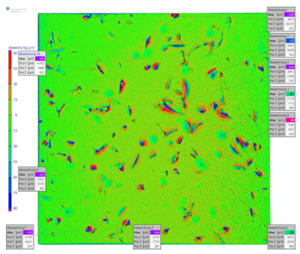

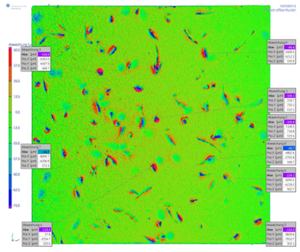

To confirm the reproducibility in accordance with the required norms, comparative tests were carried out using the different procedures and documented. With the help of imaging techniques, the damage patterns were analysed, measured and compared using statistical evaluation. With this the correlation between the two methods can be demonstrated.

Technical Data

- Maximum impact speed:

140 km/h (39 m/s) / 300 km/h (83 m/s) - Angle adjustment: horizontal/vertical

- Height adjustment: up to 700 mm

- Maximum grain size of discharge material:

15 mm / 40 mm - Weight (without switching cabinet): ca. 800 kg

- Measurements (without switching cabinet):

L=2300mm, W=1100mm, H=2000mm