- Business Fields

- Automotive

-

Springs

- Fatigue strength of axle springs

- Fatigue strength of valve springs

- Corrosion Spring Testing Machine (CSTM)

- Dry Spring Testing Machine (DSTM)

- Valve Spring Testing Machine (VSTM)

- Variable Test Rig for Resilient Components (VTRC)

- Grit Impact Simulator Machine (GISM)

- Rotating Bending Test Machines (RBTM)

- Large Spring Testing Machine (LSTM)

- Spring Coil Test Machine (SCTM)

-

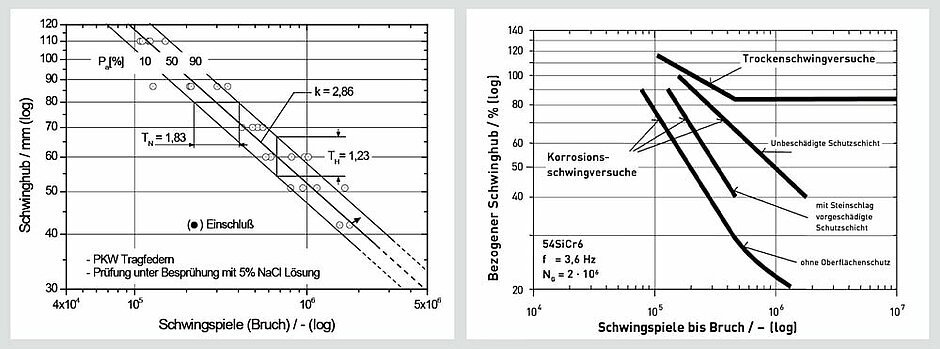

Fatigue strength of axle springs

Fatigue strength of axle springs

Relevant influences

- Mechanical loading as a result of

- Spring compression

- Axle kinematics

- Corrosive environmental conditions

- Damage to surface and coating caused by

- Spring seat abrasion

- Stone impact

Experimental verification

- Pre-damage caused by stone impact

- Corrosion in alternating cycle tests developed by the German Association of the Automotive Industry (Verband der Automobilindustrie, VDA)

- Optional tests with simulated compression kinematics

- Tests with original spring seats in installation position

- Vibration fatigue tests with fixed or variable amplitudes

- Abrasive wear simulation

- Corrosion simulation with intermittent salt-water spray exposure

- Statistical validation with systematic testing and a sufficient number of test items

Benefits of IABG spring test benches

- Energy efficiency by utilising the principle ofresonance in tests

- Reliability and low maintenance

- Exclusion of exogenic forces and vibrations

- Testing with parallel and circular deflection

- Tests with original spring seats ininstallation position

- Dry and wet fatigue tests

- Optional application of abrasive mediato spring seat

- Software-based testing, documentationand evaluation

- Accepted by all leading car manufacturers

- Compliant with German OEM standards (AK-LH07) for springs and stabilizer bars

![[Translate to English:] Schwingfestigkeit von Achsfedern](/fileadmin/_processed_/b/0/csm_Schwingfestigkeit-Achsfedern_1_bf328c5e1e.jpg)

![[Translate to English:] Schwingfestigkeit von Achsfedern](/fileadmin/_processed_/7/2/csm_Schwingfestigkeit-Achsfedern_2_83580e1151.jpg)