- Business Fields

- Automotive

-

Springs

- Fatigue strength of axle springs

- Fatigue strength of valve springs

- Corrosion Spring Testing Machine (CSTM)

- Dry Spring Testing Machine (DSTM)

- Valve Spring Testing Machine (VSTM)

- Variable Test Rig for Resilient Components (VTRC)

- Grit Impact Simulator Machine (GISM)

- Rotating Bending Test Machines (RBTM)

- Large Spring Testing Machine (LSTM)

- Spring Coil Test Machine (SCTM)

-

Variable Test Rig for Resilient Components (VTRC)

Variable Test Rig for Resilient Components (VTRC)

The development and quality monitoring of high stressed spring components of vehicles like suspension springs and stabilizer bars demand fatigue tests under near-service conditions. The main quality features to be tested are, for instance, fatigue strength and relaxation behaviour under near to reality load and environmental conditions.

Based on these requirements IABG offers an energy-efficient test rig for the testing of resilient components under saltwater corrosion, with different temperatures or under laboratory conditions for a time and cost saving determination of fatigue strength.

Benefits of the IABG Test Rig

- Energy efficiency by testing with a new actuator concept

- Implementation of cycling tests

- Testing in the frequency range under 2 Hz

- Testing of single and multi-level realtime signals

- Testing at different temperatures and/or incorrosive media

- Free configuration of test components in clamping area

- Testing of springs/stabilizer bars with original stabilizer bar bearings and assembly tests in full axle configurations

Testing of coiled springs in axle configuration

Technical data

- Maximum load allowed for each test station:

Fmax = 35 kN - Max. Maximum number of test stations: 4

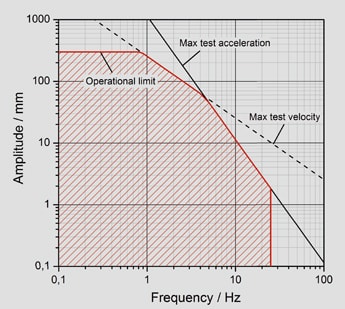

- Cycle stroke and test frequency: see performance chart

- Testing of resilient components like springs and stabilizer bars

- Parallel deflection or simulation of axle kinematics

- Free confi guration with complete vehicle axle

- Optional testing at different temperatures, levels of humidity and types of corrosion

- Weight/dimensions of the test rig:

- 5,5 t, L = 3200 mm, W = 2200 mm, H = 2850 mm

- Additional space required for control console, power electronics and corrosion unit