- Business Fields

- Automotive

-

Springs

- Fatigue strength of axle springs

- Fatigue strength of valve springs

- Corrosion Spring Testing Machine (CSTM)

- Dry Spring Testing Machine (DSTM)

- Valve Spring Testing Machine (VSTM)

- Variable Test Rig for Resilient Components (VTRC)

- Grit Impact Simulator Machine (GISM)

- Rotating Bending Test Machines (RBTM)

- Large Spring Testing Machine (LSTM)

- Spring Coil Test Machine (SCTM)

-

Valve Spring Testing Machine (VSTM)

Valve Spring Testing Machine (VSTM)

Despite the very low cost per part of valve springs compared to the total engine component cost, the valve spring is still a safety-critical component. It is vital that valve spring failure be prevented entirely, for if a failure should occur it could result in total engine failure. The high risk involved with valve spring failure to the overall engine means the measures taken to ensure spring quality are of great significance.

The IABG Valve Spring Testing Machine allows the efficient determination of the fatigue strength of valve springs under the influence of temperature, saving both time and money. The test machine operates using resonance principles, and is able to simultaneously test a large number of valve springs up to their maximum possible stress achieving a statistically reliable result with minimal effort.

Advantages of the IABG Valve Spring Test Machines

- Energy efficiency by utilising the principles of resonance in tests

- Reliability and low maintenance

- Designed to exclude all external forces and vibrations

- Simultaneous testing of a large number of springs

- Fatigue test at various temperatures

- Software-based testing, documentation and evaluation

- Accepted by all leading car manufacturers

Relevant influences

- Mechanical demand from compression

- Very high amount of load cycles

- Working environment with increased temperatures

- Dynamic settling as a result of many load cycles

Experimental verification

- Fatigue resistance design of valve spring on the basis of safety requirements

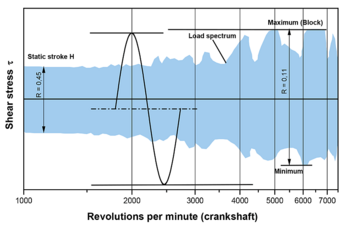

- Tests with maximum stress, just before block length of the spring

- Fatigue tests with fixed amplitudes

- Simultaneous testing of a large number of springs

- Simulation of environmental conditions incl. increased temperature

- Statistical validation with systematic testing and a sufficient number of test items

- Determination of dynamic setting

Technical data

- Maximum permissible load per test position: Fmax = 20 kN

- Maximum permissible mean load over the two test areas: Fm, max = 13 kN

- Maximum possible stroke: H = 80 mm

- Maximum possible mounting height: L = 250 mm

- Test frequency:

fo = 0,6 √(n·R) [Hz] = 2 to 30 Hz

n = Number of test specimens tested

R = Spring rate [N/mm] - Temperature control: Tmax = up to 200 °C

- Constant or randomly variable amplitudes (block program)